Innovation in beauty packaging – the 84.9mm Black Lip Balm Lip Gloss Lipstick Capsule. Crafted with precision and elegance, this capsule is designed to elevate your lip care and cosmetic products to n...

The Unseen Science of the Cosmetic Well Pump: Why Packaging Matters More Than You Think

The Silent Guardian of Your Skincare

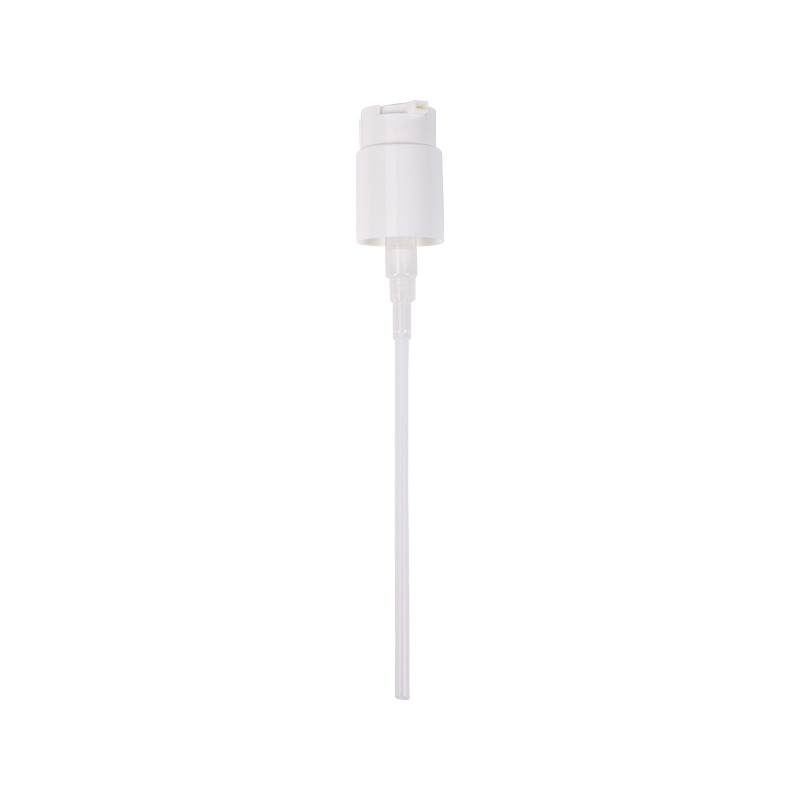

Every morning, you press down on a dispenser and out comes a perfect dollop of your favorite serum or foundation. This seemingly simple action is the result of a small, sophisticated piece of engineering known as the Cosmetic Well Pump. While the ingredients inside the bottle get all the attention, this unsung hero of packaging is critical to the efficacy, safety, and overall experience of your beauty products. It is the crucial interface between the delicate formula and the outside world.

Beyond the Diptube: The Anatomy of Dispensing

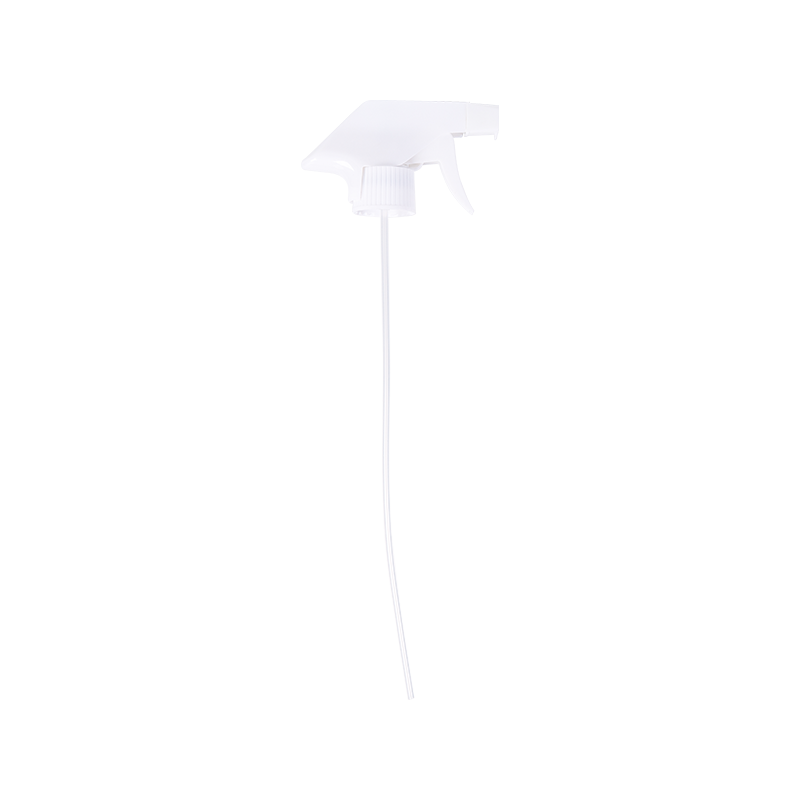

Most people picture a traditional pump with a straw-likediptubereaching to the bottom of the bottle. While effective for less sensitive or thicker products like body lotions, the modern cosmetic industry—especially high-end skincare—increasingly relies on more advanced systems.

At its core, any pump is a type ofpositive-displacementmechanism. Pressing theactuator(the part you push down) moves a piston inside a chamber. This movement forces a set, precise volume of product out through the nozzle. When you release the actuator, the piston retracts, drawing a new volume of product into the chamber from the reservoir, ready for the next use.

The Revolutionary Airless Pump System

For products containing high concentrations of potent, sensitive active ingredients like Vitamin C, retinol, or delicate peptides, a traditional pump can be a death sentence. Repeated exposure to air through the diptube and the pump mechanism causes oxidation, which degrades the ingredients and renders them less effective, or even useless.

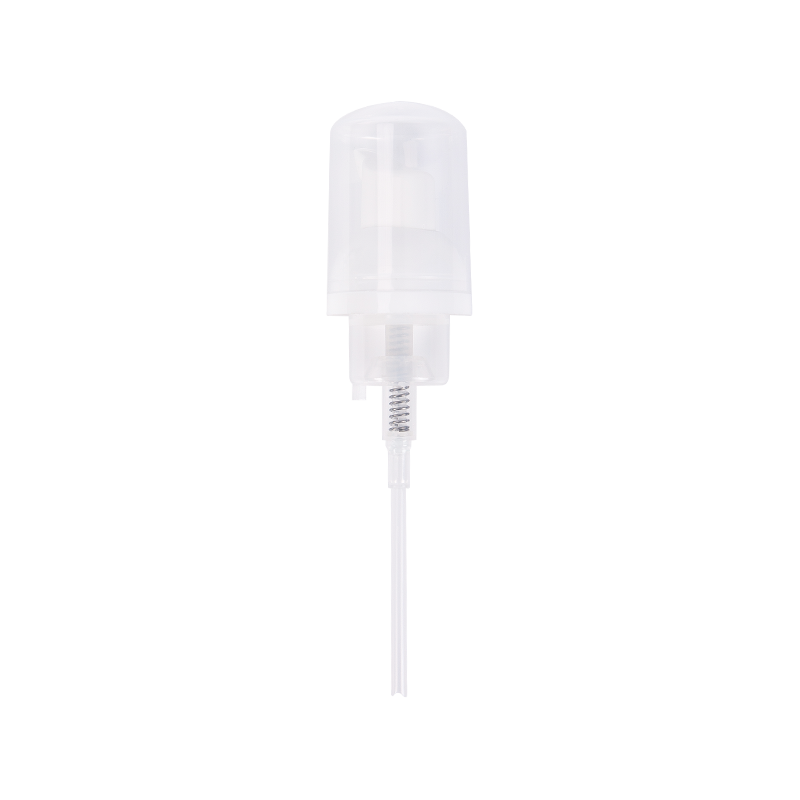

Enter the airless pump, a true marvel of chemical engineering packaging.

The Vacuum-Seal Advantage

The airless system fundamentally redesigns how the product is extracted. Instead of using a diptube, the container is built with a piston at the bottom. When the actuator is pressed, the pump creates a vacuum that causes this disc-shaped piston to rise, pushing the product upwards and out of the nozzle.

-

No Air Backflow: Since the system does not rely on replacing the dispensed product volume with air, oxygen never enters the container. This maintains the formula's stability and extends its shelf life significantly, often eliminating the need for higher concentrations of synthetic preservatives.

-

Complete Evacuation: The piston ensures that virtually every last drop of product is pushed out of the container. This is a huge benefit for consumers, who often complain about being unable to access the final 5-10% of product in a traditional bottle, and it is a win for sustainability by reducing product waste.

-

Consistent Dosing: Airless systems are engineered to dispense an extremely precise and consistent amount with every full pump—a critical feature for potent products where accurate dosage is essential for both safety and effectiveness.

A Marriage of Form and Function

The Cosmetic Well Pump is not just about engineering; it is also a key element of the consumer experience and brand identity. For luxury brands, the feel and look of the pump contribute to the perception of quality. A smooth, controlled actuation, a satisfying 'click,' and a visually appealing metallic or frosted finish all elevate the ritual of applying the product.

In an industry where a fraction of a percent of an active ingredient can drastically change a formula’s performance, the pump acts as the final quality control barrier. It ensures that the billion-dollar formula developed in the lab arrives on your skin exactly as the cosmetic chemists intended: fresh, stable, and in the perfect dose. The science is sealed in the package, making the Cosmetic Well Pump a core, indispensable technology in modern beauty.

中文简体

中文简体