Innovation in beauty packaging – the 84.9mm Black Lip Balm Lip Gloss Lipstick Capsule. Crafted with precision and elegance, this capsule is designed to elevate your lip care and cosmetic products to n...

Precision & Protection: The Ultimate Guide to Selecting and Using Dropper Bottles for Pro-Grade Products

Understanding Material Compatibility for Dropper Bottles

Selecting the right material for a dropper bottle is the most critical step in ensuring product longevity and chemical stability. Glass remains the industry gold standard for essential oils and high-potency serums because it is non-reactive and impermeable. Specifically, borosilicate glass is preferred for lab-grade applications due to its resistance to thermal shock. For products that are light-sensitive, such as Vitamin C or Retinol, amber or cobalt blue glass is essential as it filters out damaging UV rays that can cause oxidation and degradation of the active ingredients.

Plastic alternatives, such as LDPE (Low-Density Polyethylene) and PET (Polyethylene Terephthalate), offer different advantages. LDPE is prized for its flexibility, making it ideal for "squeeze" applications like eye drops or e-liquids where controlled manual pressure is required. PET, on the other hand, provides a high-clarity, glass-like appearance while being lightweight and shatterproof, making it an excellent choice for travel-sized beauty products and retail environments where shipping weight and durability are primary concerns.

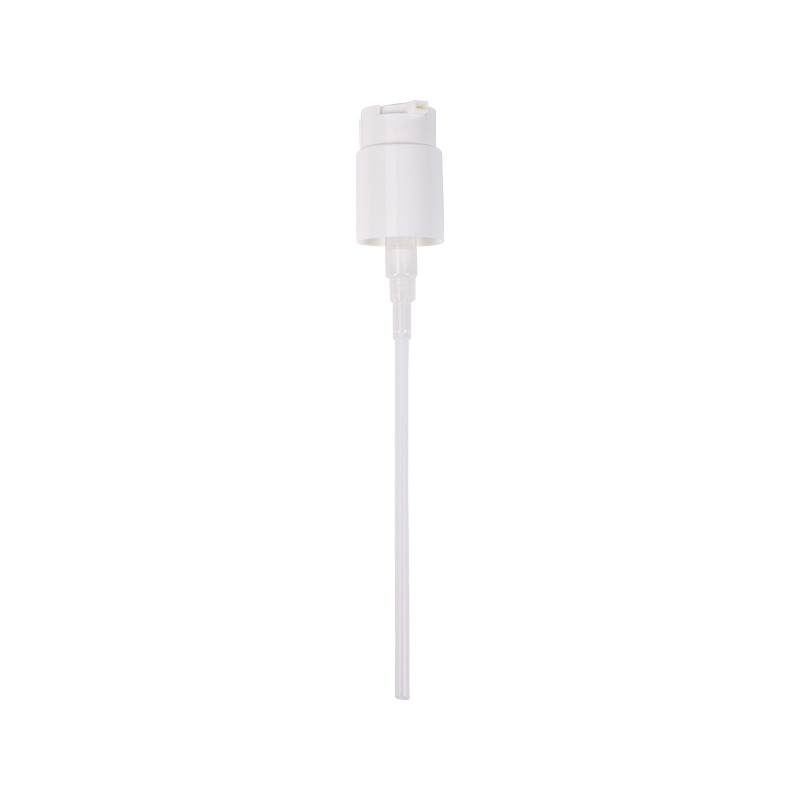

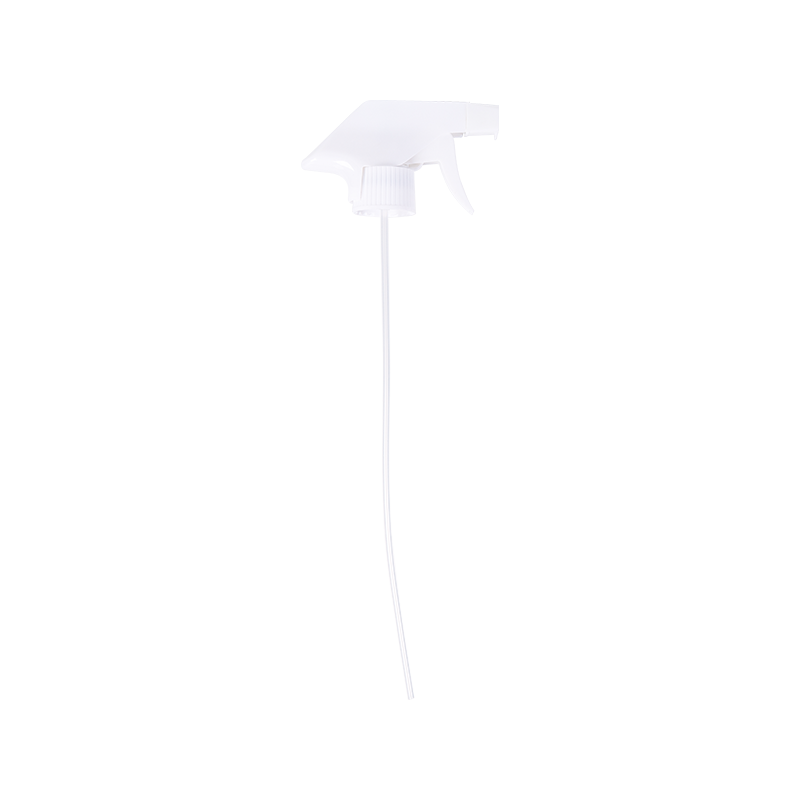

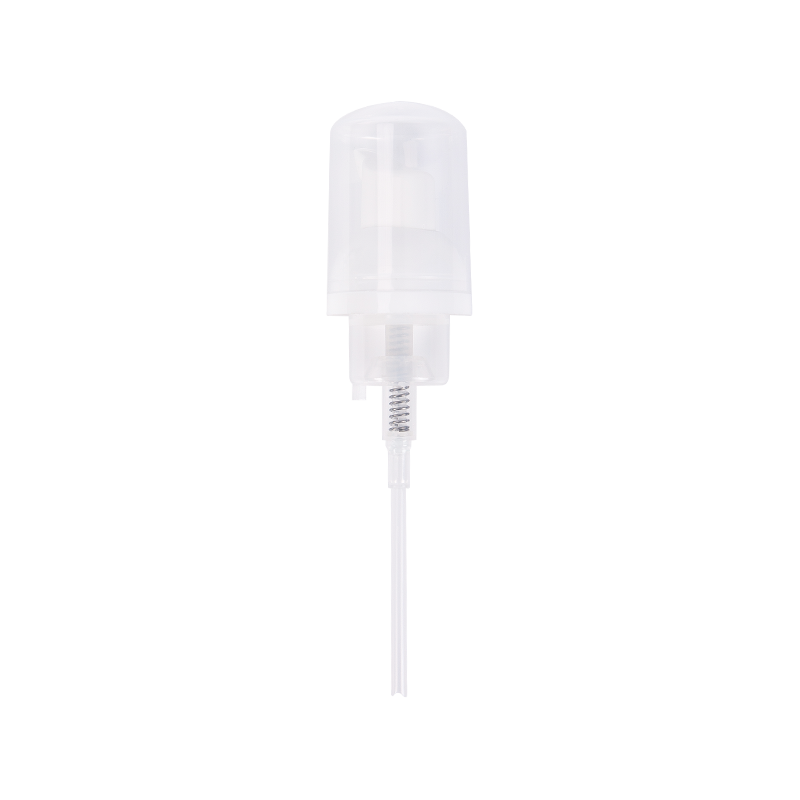

The Anatomy of a Precision Dropper Assembly

A dropper bottle is only as effective as its closure system. The assembly typically consists of three parts: the pipette, the bulb, and the cap. Pipettes are usually made of glass or plastic and can be calibrated with printed measurements to ensure dosage accuracy. The bulb, often made of rubber or TPE (Thermoplastic Elastomer), must be compatible with the liquid inside; for instance, certain essential oils can degrade natural rubber, requiring a synthetic elastomer to prevent the bulb from becoming tacky or leaking.

When choosing a closure, consider the following technical specifications to ensure a vacuum-tight seal and user safety:

- Neck Finish: Common sizes like 18-400 or 20-400 must match exactly between the bottle and the cap to prevent evaporation.

- Child-Resistant Closures (CRC): Essential for products containing nicotine, cannabinoids, or concentrated chemicals to meet safety regulations.

- Tamper-Evident Rings: Provide consumer confidence by showing visible proof that the bottle has not been opened since it left the manufacturer.

Comparison of Dropper Bottle Types and Applications

To help you determine which configuration best suits your specific use case, refer to the table below which highlights the primary differences in functionality and typical industry usage.

| Bottle Type | Best Used For | Key Benefit |

| Amber Glass | Essential Oils & Serums | Maximum UV Protection |

| LDPE Plastic | Eye Drops & Ink | Easy Squeeze Control |

| Clear Flint Glass | Food Coloring & Extracts | High Product Visibility |

| Calibrated Glass | Tinctures & Medicines | Precise Dosage Measurement |

Best Practices for Maintenance and Sterilization

Proper hygiene is paramount when using dropper bottles to prevent cross-contamination, especially in skincare or clinical settings. For glass bottles, autoclaving or boiling is an effective method for sterilization. However, the rubber bulbs should never be subjected to high heat for extended periods as they may melt or lose their elasticity. Instead, bulbs should be cleaned with isopropyl alcohol and rinsed thoroughly.

Avoiding Secondary Contamination

A common mistake in using dropper bottles is touching the pipette directly to the skin or other surfaces. This introduces bacteria back into the bottle, which can spoil the remaining product. Users should be instructed to hold the dropper slightly above the target area and let the liquid fall freely. This simple technique extends the shelf life of preservative-free or organic formulations significantly.

Sustainable Trends in Dropper Packaging

As the industry moves toward "Green Beauty" and eco-friendly laboratory supplies, dropper bottle designs are evolving. Many brands are moving away from multi-material assemblies that are difficult to recycle in favor of mono-material droppers or "refillable" glass systems. PCR (Post-Consumer Recycled) plastics are also becoming more prevalent for the cap and bulb components, reducing the overall carbon footprint of the packaging.

In addition to material changes, concentrated "waterless" formulations are being packaged in smaller dropper bottles to reduce shipping weight and plastic waste. By focusing on high-potency liquids delivered via precision droppers, companies can offer more value to the consumer while minimizing environmental impact.

中文简体

中文简体