Innovation in beauty packaging – the 84.9mm Black Lip Balm Lip Gloss Lipstick Capsule. Crafted with precision and elegance, this capsule is designed to elevate your lip care and cosmetic products to n...

The Micro-Physics of Mist: How the Perfume Sprayer Delivers a Fine Fragrance

An Unsung Hero of Daily Rituals

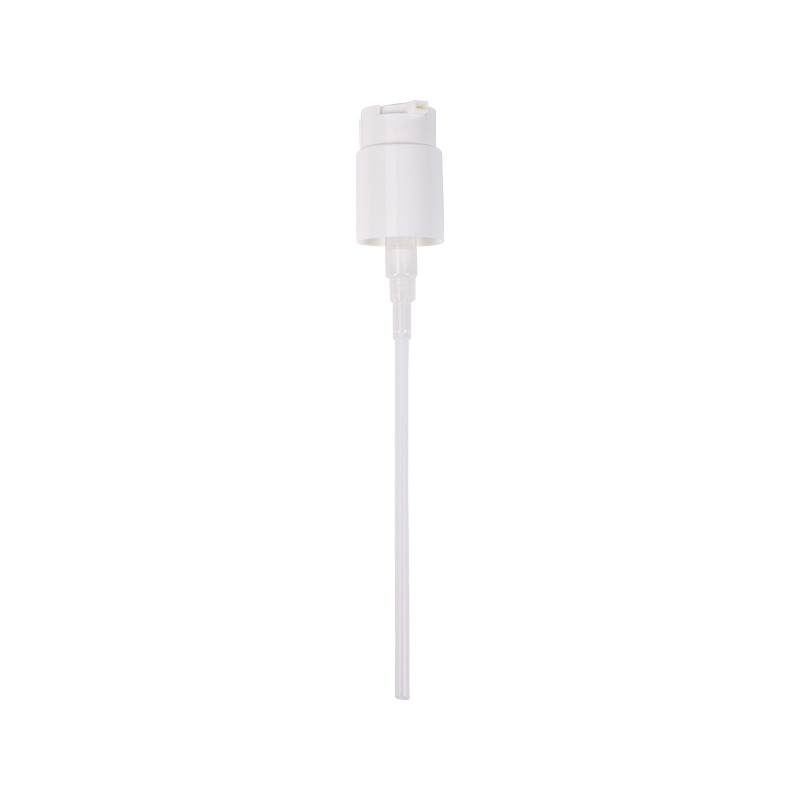

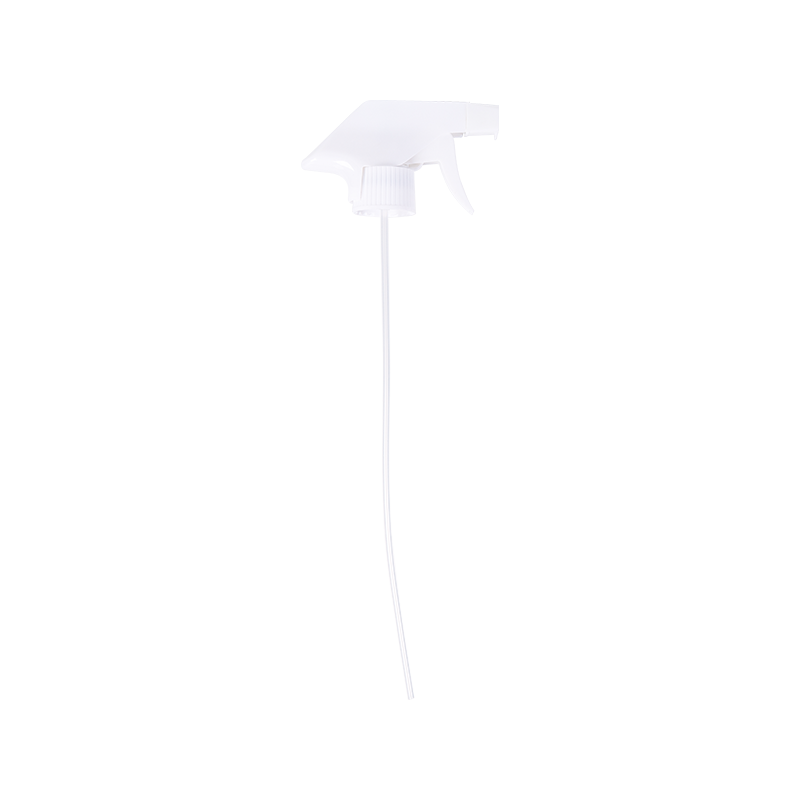

The humble Perfume Sprayer, or atomizer, is one of the most used, yet least understood, pieces of engineering in the world of personal care. This simple device is far more than just a tube and a nozzle; it is a miniature marvel of fluid mechanics that transforms a pool of liquid fragrance into a delicate, airborne mist. This transformation is not magic, but pure physics, primarily leveraging the principles that govern how fluids behave under changing pressure.

The Science of Atomization: Bernoulli's Principle in Action

The core mechanism of a classic bulb-style or a modern pump-action Perfume Sprayer relies heavily on one fundamental concept: Bernoulli's Principle.

High Speed, Low Pressure

When you depress the spray button on a modern bottle, you activate a tiny piston pump. This pump rapidly forces a jet of air (or, in more integrated designs, the fragrance itself) through a narrow, horizontal channel that crosses the top of a vertical tube—called the dip tube—which extends down into the liquid perfume reservoir.

According to Bernoulli’s Principle, an increase in the speed of a fluid (air or liquid) occurs simultaneously with a decrease in its static pressure. The air rushing across the top of the dip tube accelerates significantly as it passes through the narrowest part of the mechanism. This rapid acceleration creates a localized area of low pressure directly above the open end of the dip tube.

The Suction and Lift

The pressure inside the perfume bottle, specifically on the surface of the liquid fragrance, remains at normal atmospheric pressure, which is now significantly higher than the pressure at the top of the dip tube. This pressure difference creates a powerful force. The higher atmospheric pressure on the liquid surface pushes the perfume up the dip tube, overcoming both gravity and the liquid's surface tension, effectively creating a controlled suction.

The liquid rises and is drawn into the high-speed air stream at the nozzle exit. This is the moment the liquid fragrance leaves the internal system and is prepared for its final transformation.

From Liquid Stream to Fragrant Cloud

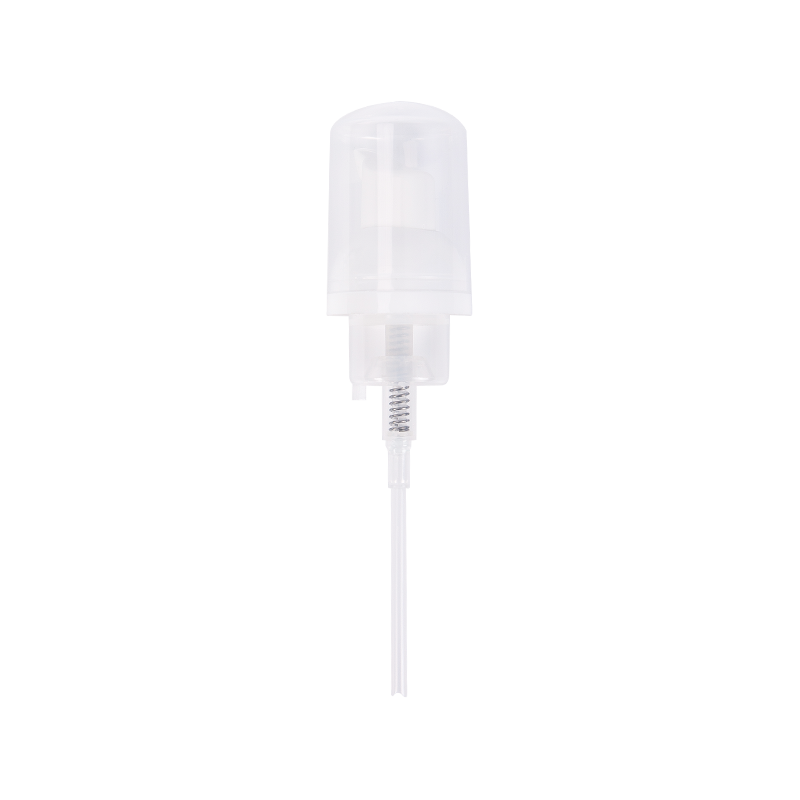

The final stage of the Perfume Sprayer mechanism is the critical process ofatomization, which gives the device its technical name: the atomizer.

Fragmentation at the Nozzle

As the liquid perfume meets the high-velocity air at the tiny exit aperture, the forces of shear stress—the friction between the fast-moving air and the slower-moving liquid—become immense. This force stretches and fragments the continuous stream of liquid into incredibly small, discrete droplets. This process is so effective that the liquid is broken down into an aerosol—a suspension of fine liquid particles in the air.

The nozzle is precisely engineered to control the size of these droplets. If the droplets were too large, the perfume would "squirt" or "dribble." If they were too fine, the fragrance would dissipate immediately. The ideal size ensures the mist travels a short distance, lands on the skin or clothing, and evaporates at a rate that allows the scent's complex notes to be experienced over time. This droplet size is typically on the order of a few tens of micrometers.

Valve Systems and Precision Dosing

Modern sprayers also incorporate sophisticated valve systems, often featuring a tiny spring-loaded ball or piston. When the button is released, this valve immediately snaps shut. This prevents the precious fragrance from leaking, maintains the air pressure seal, and—crucially—cuts off the liquid flow to ensure that only a precise, metered dose is released with each pump. This precision is essential for maximizing the life of an expensive fragrance and preventing over-application.

In essence, the Perfume Sprayer is a perfect example of applied fluid dynamics, taking a physical law over two centuries old and packaging it into an elegant, effective, and indispensable tool for the modern consumer.

中文简体

中文简体