Innovation in beauty packaging – the 84.9mm Black Lip Balm Lip Gloss Lipstick Capsule. Crafted with precision and elegance, this capsule is designed to elevate your lip care and cosmetic products to n...

The Science Behind the Fine Mist: Understanding Atomization

The Everyday Marvel of the Mist Spray Bottle

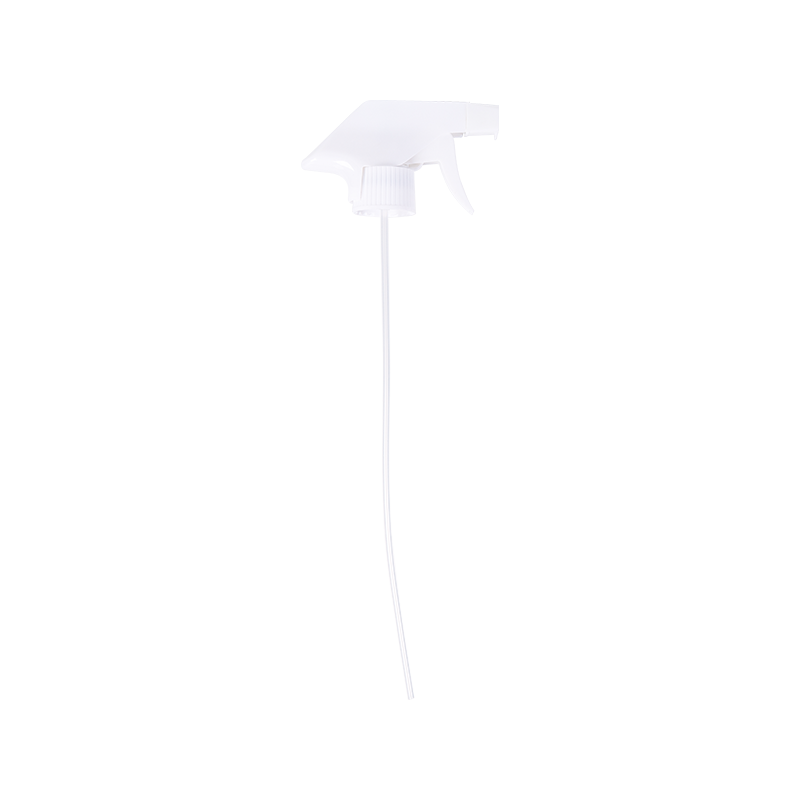

The simple act of pressing a trigger and releasing a fine cloud of liquid is something many of us do every day, whether we’re cleaning, moisturizing, or spritzing cologne. This seemingly mundane action is actually a remarkable demonstration of fluid dynamics and mechanical engineering packed into the plastic casing of a Mist Spray Bottle. But how exactly does a stream of liquid transform into a delicate, evenly distributed mist? The answer lies in the process of atomization.

What is Atomization?

Atomization is the process of breaking a bulk liquid into a spray of fine droplets. This transformation is crucial in countless applications, from fuel injection in engines to agricultural crop dusting, and even in nebulizers for medical treatments. In the context of a simple spray bottle, atomization is achieved through mechanical force and clever design.

The Role of Pressure and Nozzle Design

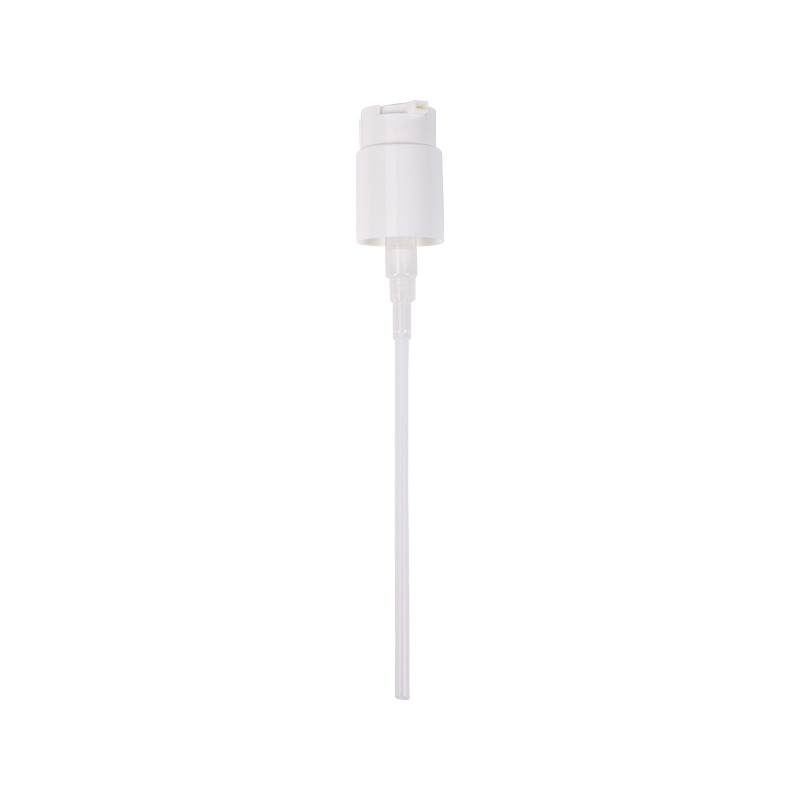

The journey of the liquid starts when you pull the trigger. This action engages a piston pump mechanism within the body of the Mist Spray Bottle.

- Pumping Action: Pulling the trigger compresses a small piston, which forces liquid from the reservoir up a dip tube and into the pump chamber.

- Creating Pressure: As the liquid is forced into the chamber, pressure builds up rapidly.

- The Critical Moment at the Nozzle: The high-pressure liquid is then forced through a tiny, precisely engineered nozzle or orifice. This nozzle is the heart of the atomization process.

The fundamental principle here is the rapid conversion of the liquid’s potential energy (due to pressure) into kinetic energy (due to high velocity). When the liquid exits the confined space of the nozzle into the low-pressure environment of the open air, the sudden drop in pressure and the high speed cause the fluid stream to become unstable.

How Droplet Size is Controlled

The quality of the mist—how fine and uniform the droplets are—is primarily determined by the nozzle geometry and the force applied.

Nozzle Types and Their Effects

Different spray applications require different droplet sizes. A garden hose sprayer creates large droplets for watering, while a perfume atomizer creates an extremely fine, almost invisible mist. The Mist Spray Bottle sits in the middle, designed to create droplets small enough to float and distribute evenly, but large enough to efficiently coat a surface.

- Swirl Chambers: Many high-quality mist nozzles, even in simple spray bottles, utilize a small internal swirl chamber. The liquid enters this chamber tangentially (at an angle), causing it to spin rapidly before exiting the final orifice. This rotational motion spreads the liquid into a very thin sheet or cone right as it leaves the nozzle, which then naturally and quickly breaks up into fine, uniform droplets.

- Impact Atomization: Some designs use a simple jet of liquid directed against a flat surface. The impact shatters the liquid into a spray.

The goal is to maximize the surface area of the liquid. By breaking the bulk liquid into millions of tiny droplets, the total surface area exposed to the air increases dramatically. This is why a fine mist can cool a surface or a person more effectively than a splash of water—the rapid evaporation from the massive surface area draws heat away quickly.

Beyond Manual Pumping: Continuous Spray Technology

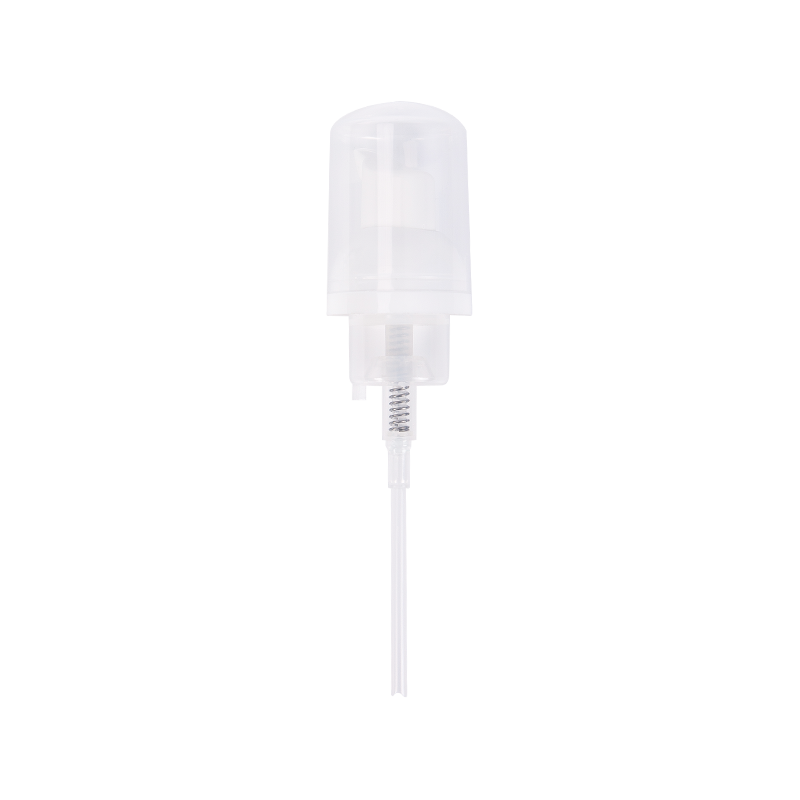

A modern innovation building on the classic Mist Spray Bottle design is the continuous mist sprayer. These bottles often feature a specialized spring-loaded pump mechanism that, with a single pull of the trigger, produces a long, continuous spray that lasts for a few seconds.

The secret to this continuous action lies in the advanced pump and accumulator system. A single trigger pull not only pumps liquid but also compresses air within a small sealed chamber, or accumulator. This stored air pressure then acts as a secondary power source, continuing to push the liquid through the nozzle at a constant rate even after the trigger has been released, providing a smooth, aerosol-like experience without the use of chemical propellants.

The Mist Spray Bottle is more than just a container and a pump; it’s a testament to how simple yet powerful mechanical principles can be used to control the fundamental nature of fluids, delivering an indispensable tool for countless tasks.

中文简体

中文简体