Innovation in beauty packaging – the 84.9mm Black Lip Balm Lip Gloss Lipstick Capsule. Crafted with precision and elegance, this capsule is designed to elevate your lip care and cosmetic products to n...

The Hidden Science of Your Perfume Sprayer

The simple act of pressing the cap on a bottle of perfume is a small miracle of engineering and physics. That elegant mist that delicately scents your skin is the result of forces and fluid dynamics, all neatly packaged in a device known as an atomizer or perfume sprayer. It’s not just a fancy cap; it’s a sophisticated machine that transforms a liquid into a fine, evenly dispersed cloud.

The Anatomy of the Atomizer

Every perfume sprayer, from the inexpensive travel size to the high-end crystal flacon, operates on the same basic principles and shares a common structure.

The Key Components

The components work together seamlessly to create the mist.

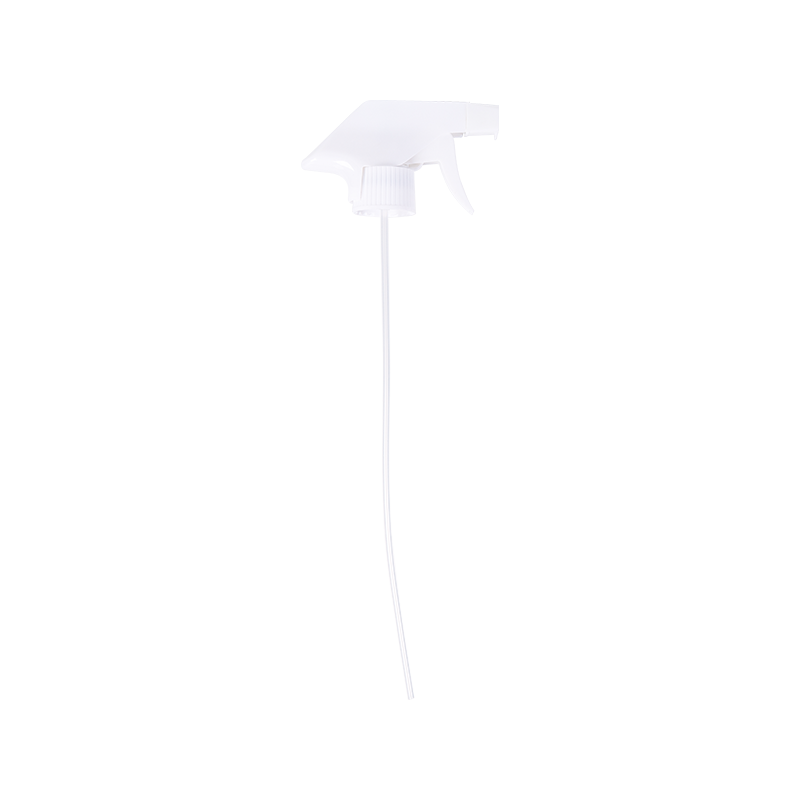

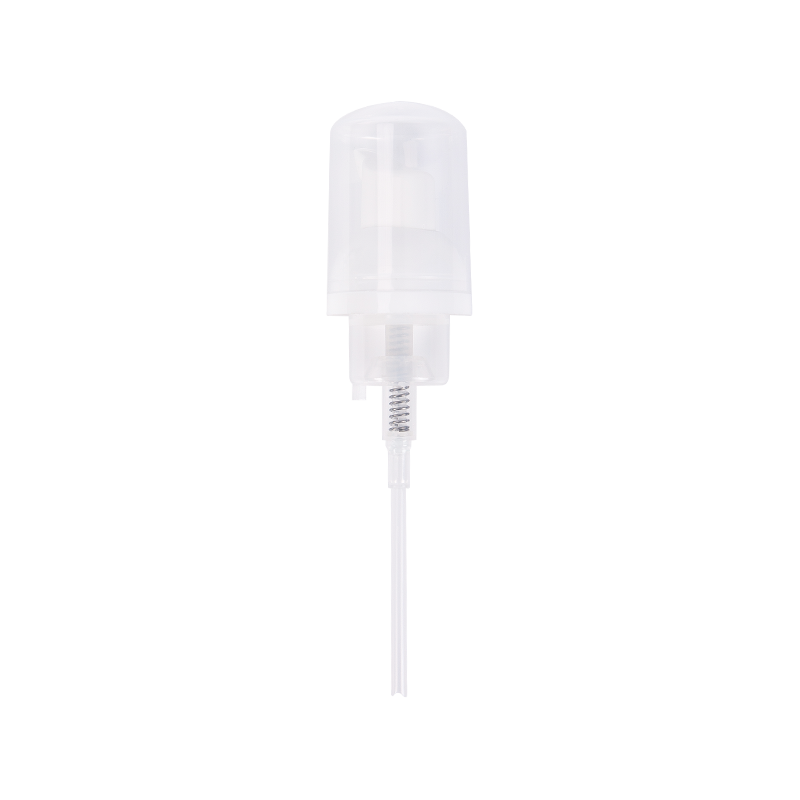

- The Actuator (Cap/Nozzle): This is the button you press. It has a tiny hole where the perfume mist exits. Pressing it pushes the entire mechanism down.

- The Pump/Piston: Hidden beneath the actuator, this part is responsible for the actual “pumping” action, creating a vacuum and pressure.

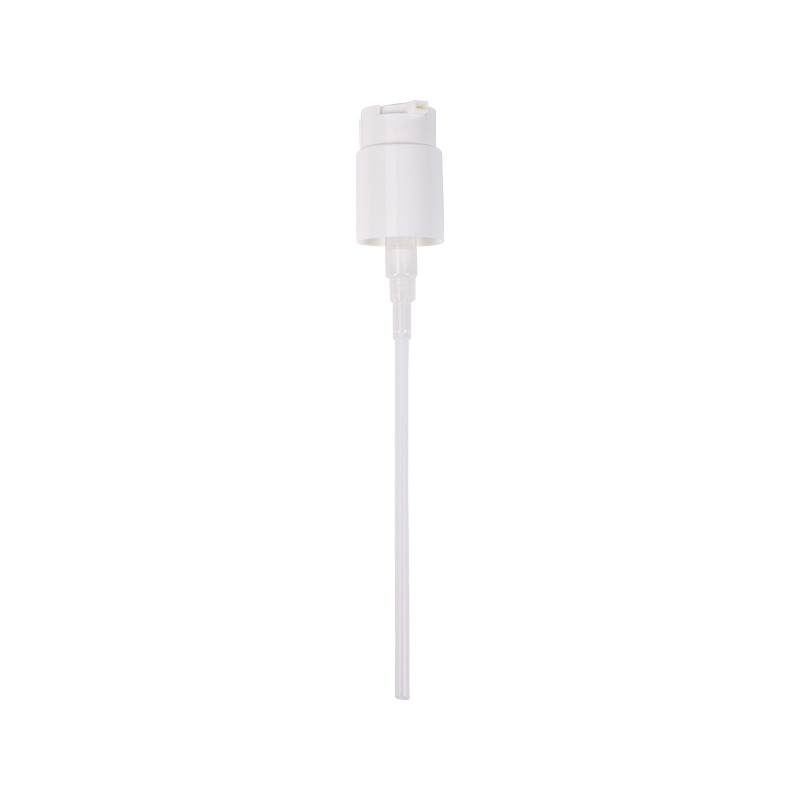

- The Dip Tube: This long, slender plastic tube extends from the pump down into the perfume liquid in the bottle. This is the straw that draws the liquid up.

- Valves (Ball and Spring): These tiny components are the gatekeepers. They control the direction of the fluid flow, ensuring liquid moves up and not back down, and that air doesn’t leak in.

How Pressure Creates Perfume Mist

The mechanism that turns liquid into mist is based on a principle of fluid dynamics discovered in the 18th century by Swiss mathematician Daniel Bernoulli, known as the Bernoulli effect.

The Bernoulli Effect in Action

The key to the sprayer’s function is the creation of a low-pressure zone inside the nozzle.

- Pressing Down: When you press the actuator, the pump/piston is driven downward, compressing a tiny spring. This action pushes any perfume remaining in the chamber out through the nozzle hole as a fine jet.

- The Vacuum Effect: As the spring returns the piston to its original position, it temporarily creates a vacuum (a region of extremely low pressure) within the pump chamber.

- Lifting the Liquid: Nature abhors a vacuum. The relatively higher atmospheric pressure pushing down on the surface of the liquid inside the bottle forces the perfume up the dip tube to fill the low-pressure chamber. This is the same principle that makes a straw work.

- Atomization (The Mist): The real magic happens at the nozzle. The pump forces the liquid through the extremely small aperture at high speed. As the jet of liquid rapidly exits into the open air, the surface tension holding the liquid together is overcome by the turbulence and drag forces of the air. This causes the stream to break up instantly into millions of minuscule droplets, creating the aerosol or mist you smell. This process is called atomization.

The smaller the aperture and the faster the liquid is expelled, the finer the mist, which is crucial for an even application and for maximizing the perfume’s sillage (the trail of scent it leaves).

The Chemical Impact: Why Sprayers Are Essential

A sprayer is more than just a convenient dispenser; it’s a necessity for preserving and delivering the chemical complexity of the fragrance.

Protecting the Fragrance

Perfumes are delicate blends of essential oils and aroma compounds dissolved in alcohol. Two major enemies of perfume are oxygen and heat.

- If perfume were applied by simply dabbing from an open bottle, every use would expose the entire liquid to a fresh dose of oxygen, which would quickly oxidize the fragrance molecules, causing the scent to change and eventually spoil.

- Because the atomizer is a sealed system, it only exposes the tiny amount of liquid in the chamber to the outside air during a spray, keeping the bulk of the fragrance well-preserved inside the bottle for years.

The humble perfume sprayer is a perfect example of how applied physics and simple mechanical principles enhance a daily ritual, turning an expensive liquid into a delightful, evenly distributed, and long-lasting sensory experience.

中文简体

中文简体