Innovation in beauty packaging – the 84.9mm Black Lip Balm Lip Gloss Lipstick Capsule. Crafted with precision and elegance, this capsule is designed to elevate your lip care and cosmetic products to n...

The Airless Bottle Revolution: Protecting Potency and Preserving Products

The beauty and personal care industry is constantly seeking innovative packaging solutions to maximize product efficacy and shelf-life. Among the most significant advancements in recent years is the widespread adoption of the Airless Bottle. This sophisticated packaging system is fundamentally changing how sensitive formulations—especially those containing delicate active ingredients—are delivered to consumers, offering superior protection against environmental degradation.

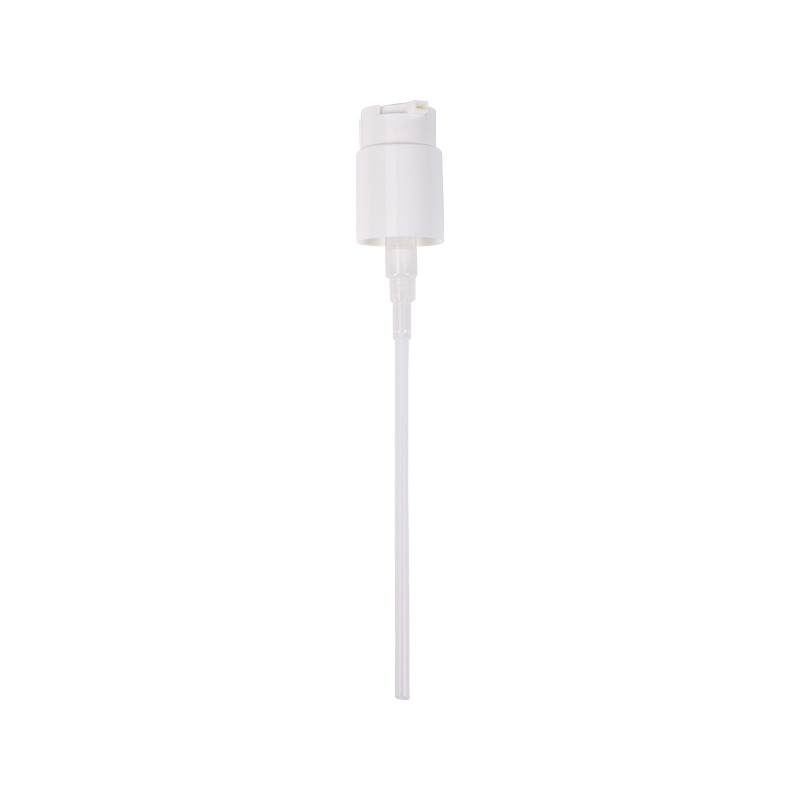

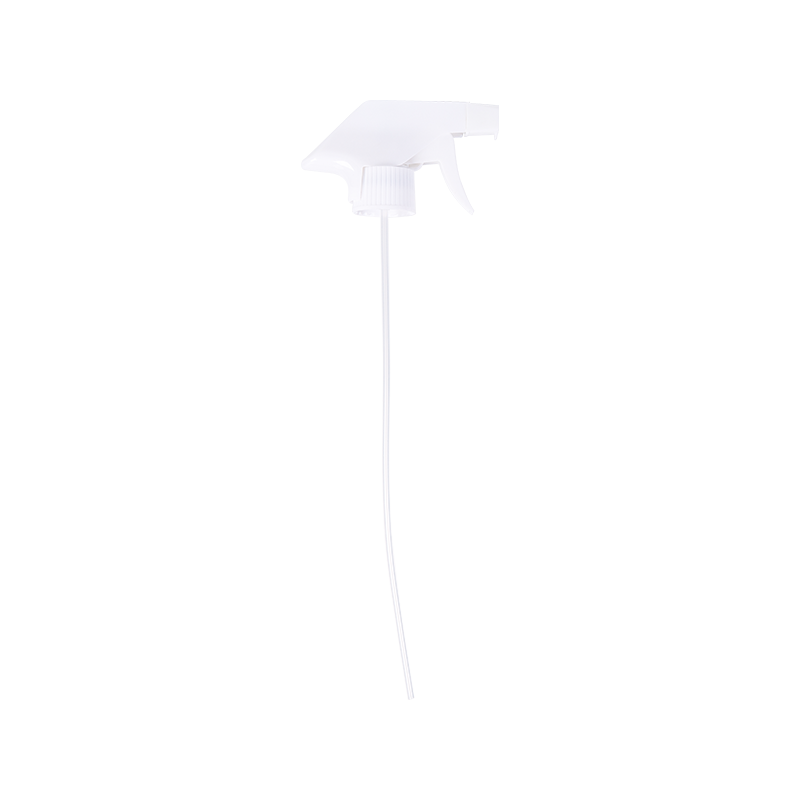

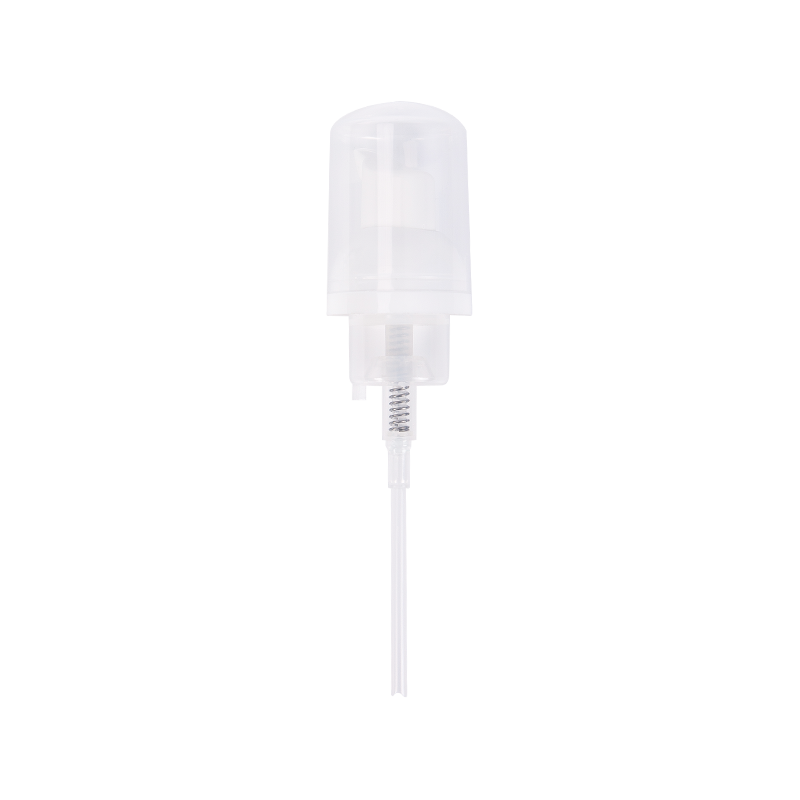

How an Airless Bottle Works: Beyond the Standard Pump

Unlike traditional pump bottles or jars, which draw air back into the container to equalize pressure as the product is dispensed, an Airless Bottle operates on a vacuum-based principle.

Key Mechanism

The defining feature is the piston mechanism housed within the bottle. When the user depresses the pump, a non-pressurized piston or plate at the base of the container rises up and pushes the product out of the nozzle. This mechanism prevents outside air from entering the bottle, maintaining an airtight seal.

The Benefits of Vacuum Dispensing

This airtight, non-pressurized dispensing system offers several crucial advantages:

- Minimized Oxygen Exposure: Oxygen is a major catalyst for the degradation (oxidation) of sensitive ingredients like Vitamin C ($L$-ascorbic acid), retinoids (Vitamin A derivatives), and delicate plant extracts. The airless design drastically minimizes this exposure, preserving the product’s intended potency over time.

- Reduced Need for Preservatives: By eliminating the contamination pathway for airborne bacteria and mold, the need for high concentrations of synthetic preservatives can be reduced, appealing to consumers seeking “cleaner” formulations.

- Superior Product Evacuation: The piston mechanism ensures that almost all of the product can be dispensed—often reaching a 95-99% evacuation rate—minimizing product waste and maximizing consumer value.

- Consistent Dosing: Airless pumps often provide a more controlled and consistent dose with each pump, which is critical for highly potent or expensive treatment-based serums and creams.

Ideal Applications: When an Airless Bottle is Essential

While an Airless Bottle can be used for any liquid or cream, it is particularly essential for specific categories of formulations where ingredient stability is paramount:

| Product Category | Ingredient Sensitivity | Why Airless is Necessary |

|---|---|---|

| Antioxidant Serums | Vitamin C, Ferulic Acid | Highly prone to oxidation (turning brown/yellow) upon air exposure. |

| Retinoid Products | Retinol, Tretinoin | Degrade rapidly when exposed to light and air, losing efficacy. |

| Natural/Organic Creams | Plant oils, minimized preservatives | Lack of strong chemical preservatives necessitates an airtight environment to prevent microbial growth. |

| Sensitive Pharmaceuticals | Topical medications, compounded items | Requires a sterile, consistent environment to ensure drug stability. |

The Future of Packaging: Sustainability and Innovation

While the focus remains on protection, the industry is also pushing for more sustainable airless solutions. Manufacturers are developing mono-material airless bottles to simplify recycling, as well as refillable systems that utilize disposable airless pouches or cartridges housed within a durable outer shell.

The Airless Bottle is no longer just a luxury packaging option; it is becoming the gold standard for any brand committed to delivering maximum efficacy and safety for their high-performance formulations. It represents a critical convergence of packaging technology and cosmetic chemistry, ensuring that the last drop of a product is as potent as the first.

中文简体

中文简体