Innovation in beauty packaging – the 84.9mm Black Lip Balm Lip Gloss Lipstick Capsule. Crafted with precision and elegance, this capsule is designed to elevate your lip care and cosmetic products to n...

The Essential Role and Evolution of Cosmetic Plastic Bottles

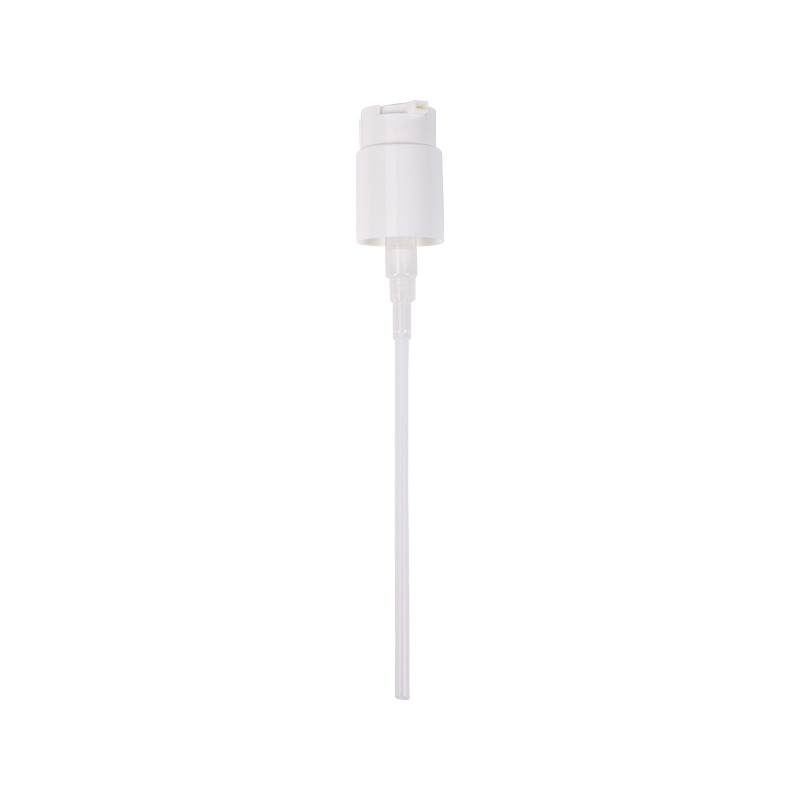

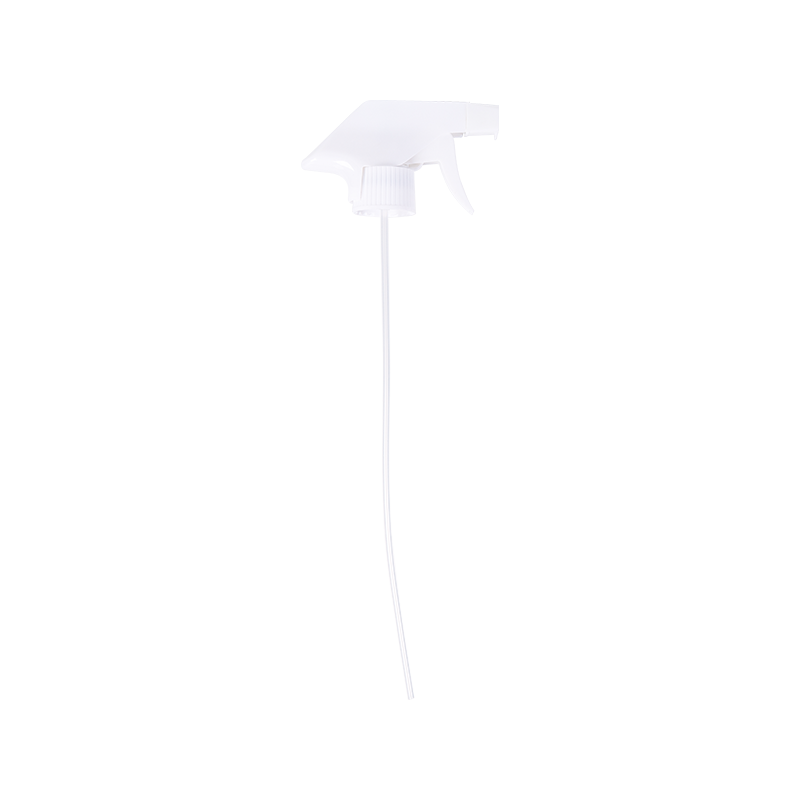

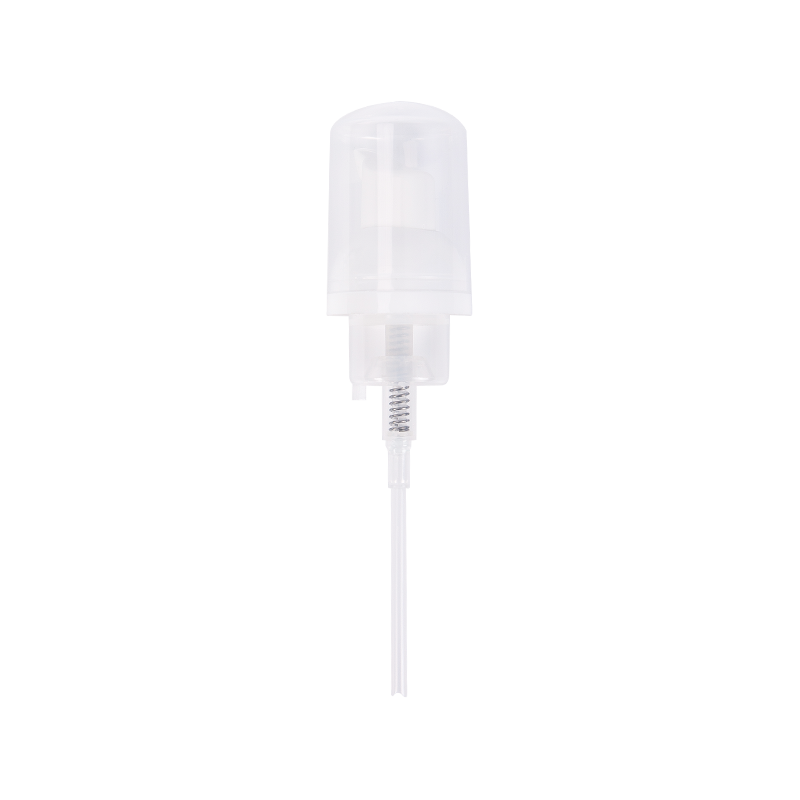

Cosmetic Plastic Bottles are one of the most ubiquitous packaging formats in the global beauty and personal care industry. Far more than simple containers, these bottles play a critical, multifaceted role in the product's lifespan, from manufacturing and shelf presentation to consumer use and eventual disposal. Their widespread adoption is due to a unique blend of functionality, cost-effectiveness, and design flexibility.

Core Functionality: Protection and Preservation

The primary function of any cosmetic container is to protect the formula inside, and Cosmetic Plastic Bottles excel at this.

-

Chemical Stability: Different plastic polymers (like PET, HDPE, PP, and PVC) are chosen based on the chemical compatibility with the product. For instance, HDPE (High-Density Polyethylene) is commonly used for thicker lotions and shampoos due to its resilience and chemical resistance, while PET (Polyethylene Terephthalate) is favored for clear, high-visibility packaging.

-

Barrier Properties: Plastic provides an excellent barrier against external contaminants like moisture, air, and bacteria, which can cause product degradation, oxidation, or spoilage. Specialized designs, such as airless pump bottles, further enhance protection by preventing air from entering the container, significantly extending the shelf life of sensitive, preservative-light formulas like serums and eye creams.

-

Safety and Durability: Unlike glass, plastic is lightweight and non-shattering, making it a safer option for products used in wet environments (like the shower) or for products marketed to children. This durability also reduces breakage during transport and handling.

Design and Aesthetic Versatility

The versatility of plastic allows for endless creative possibilities, making Cosmetic Plastic Bottles a key element in brand identity.

-

Shapes and Sizes: Plastic can be molded into virtually any shape—from sleek, minimalist cylinders to complex, ergonomic forms—allowing brands to differentiate themselves visually on the shelf.

-

Color and Transparency: The material can be fully opaque to protect light-sensitive ingredients, translucent, or completely clear for showcasing the product's texture and color. A wide spectrum of colors can be infused during the manufacturing process.

-

Finishing Techniques: Plastic surfaces can be treated with various finishes, including matte, glossy, frosted, or soft-touch, further elevating the perceived luxury and tactile experience of the product. Decorative elements like silk-screening, hot stamping, and labeling add the final branded touches.

The Sustainability Evolution

In recent years, the material choice and end-of-life cycle of Cosmetic Plastic Bottles have come under intense scrutiny, driving major innovations within the industry:

-

Post-Consumer Recycled (PCR) Plastic: A significant trend involves using plastics made from recycled materials, notably PCR-PET or PCR-HDPE. This gives a second life to existing plastic waste, reducing reliance on virgin (new) fossil-fuel-derived plastic and supporting the circular economy.

-

Refillable Systems: Many brands are shifting to durable plastic outer bottles designed to be kept and reused, offering consumers cost-effective and environmentally friendly refill pouches or inserts.

-

Material Reduction and Monomaterials: Companies are actively working to lightweight their bottles to use less plastic per unit and designing packaging from a single type of plastic (monomaterial) to simplify the sorting and recycling process.

In conclusion, the modern Cosmetic Plastic Bottles embody a balance of essential functionality—protecting and preserving valuable cosmetic formulas—and aesthetic design that drives consumer engagement. The industry's current focus on utilizing PCR content, implementing refill systems, and optimizing design for end-of-life circularity highlights plastic's ongoing evolution as a packaging workhorse in the beauty sector.

中文简体

中文简体