Innovation in beauty packaging – the 84.9mm Black Lip Balm Lip Gloss Lipstick Capsule. Crafted with precision and elegance, this capsule is designed to elevate your lip care and cosmetic products to n...

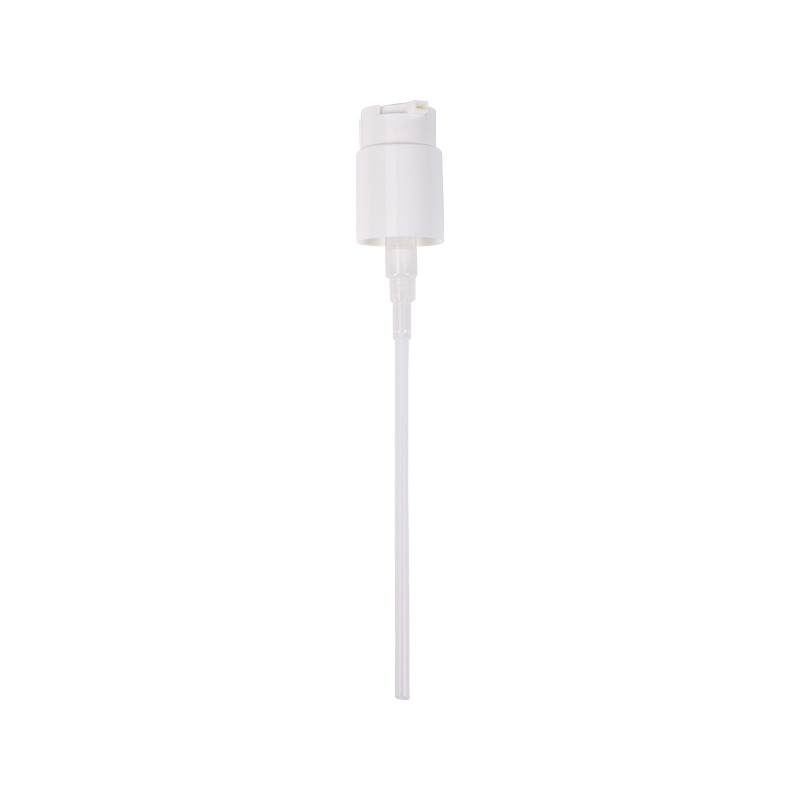

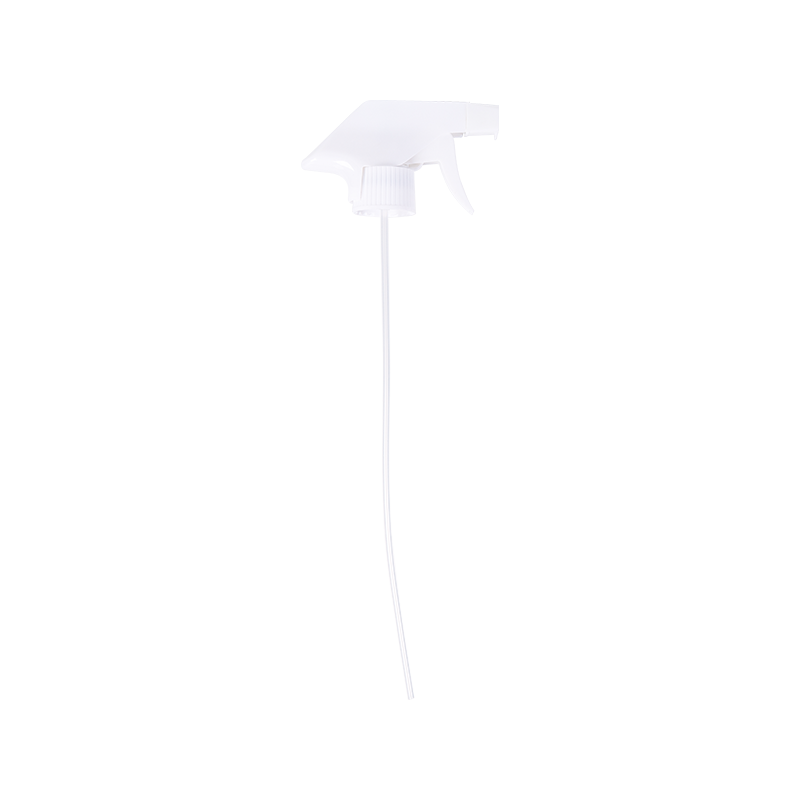

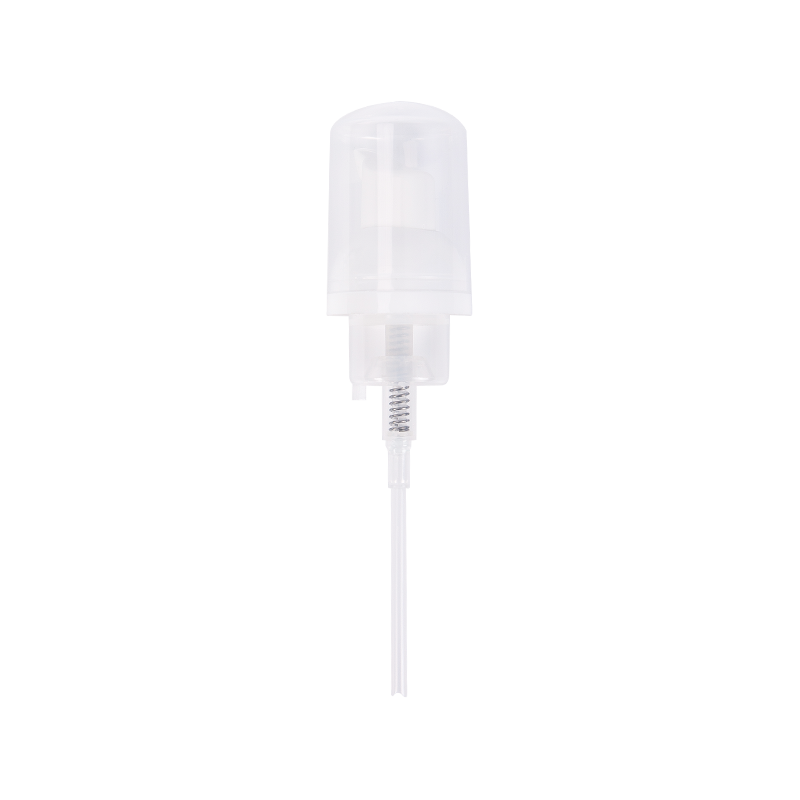

How does the trigger sprayer's pre-compression pump technology ensure consistent spray output?

The trigger sprayer technology in trigger sprayers ensures consistent spray output through a combination of mechanical design, pressure regulation, and material compatibility. Here's how it works:

1. Mechanical Design and Pressure Buildup

Pre-Compression Chamber: Before the trigger is fully depressed, the pump mechanism creates a sealed chamber where liquid is drawn in and compressed. This process builds up internal pressure before the liquid is expelled through the nozzle.

Spring-Loaded Piston: A spring-loaded piston within the pump ensures that the compression cycle is consistent. When the trigger is released, the spring returns the piston to its original position, drawing in fresh liquid and preparing for the next spray.

2. Pressure Regulation

Consistent Pressure Release: The pre-compression mechanism ensures that the liquid is released at a uniform pressure, regardless of how quickly or forcefully the trigger is depressed. This prevents variations in spray output that can occur with non-pre-compression pumps.

Valve System: Check valves or ball valves within the pump prevent backflow and maintain pressure within the system, ensuring that the liquid is only expelled when the trigger is fully engaged.

3. Material and Manufacturing Precision

High-Precision Components: The pump, piston, and other internal components are manufactured to tight tolerances, reducing the risk of leaks or inefficiencies that could affect spray consistency.

Chemical Compatibility: The materials used in the pump (e.g., plastics, seals, and springs) are chosen for their compatibility with a wide range of liquids, ensuring that they do not degrade or swell over time, which could disrupt the pre-compression process.

4. Nozzle Design

Optimized Spray Pattern: The nozzle is designed to work in conjunction with the pre-compression pump to produce a fine, consistent mist or stream. The size and shape of the nozzle orifice, along with the internal swirl chamber (if present), help atomize the liquid into uniform droplets.

5. User Experience and Ergonomics

Trigger Mechanism: The trigger is designed to provide a smooth, consistent action, allowing the user to apply the same amount of force each time. This, combined with the pre-compression pump, ensures that each spray delivers the same volume of liquid.

6. Benefits of Pre-Compression Technology

Reduced Dripping: By building up pressure before the liquid is expelled, pre-compression pumps minimize dripping and ensure that the liquid is only released when the trigger is fully engaged.

Improved Efficiency: The consistent spray output allows for more precise application of liquids, reducing waste and improving the effectiveness of the product being dispensed.

7. Applications and Industries

Household Cleaning: Pre-compression trigger sprayers are commonly used in household cleaning products, where consistent spray output is essential for even coverage and efficient cleaning.

Personal Care: In personal care products like hair sprays and body mists, pre-compression technology ensures a fine, even mist that is comfortable to use and provides consistent results.

Agricultural and Industrial Applications: Pre-compression pumps are also used in agricultural and industrial sprayers, where precise application of liquids (e.g., pesticides, fertilizers) is critical.

中文简体

中文简体