Innovation in beauty packaging – the 84.9mm Black Lip Balm Lip Gloss Lipstick Capsule. Crafted with precision and elegance, this capsule is designed to elevate your lip care and cosmetic products to n...

How do I properly clean my trigger sprayer after use to prevent residue from clogging the nozzle?

1. Preparation before cleaning

Confirm the liquid type

Water-based liquids (such as detergents, water): rinse directly with clean water.

Oily or viscous liquids (such as lubricants, emulsions): Solvents (such as alcohol, isopropyl alcohol) must be used to dissolve the residue first.

Corrosive liquids (such as acidic detergents): Wear protective gloves and ensure that the container can withstand corrosion.

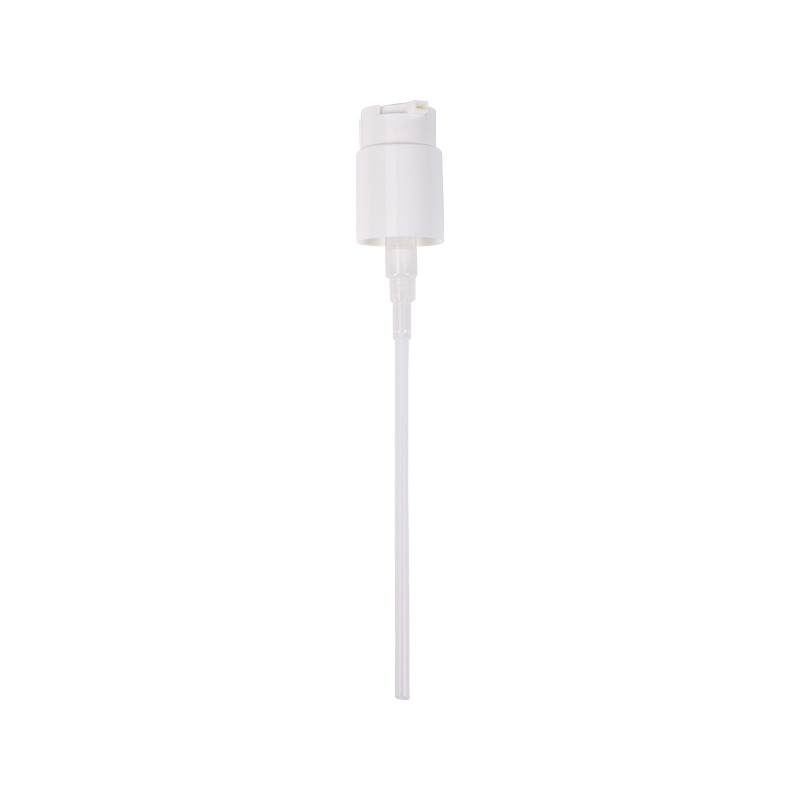

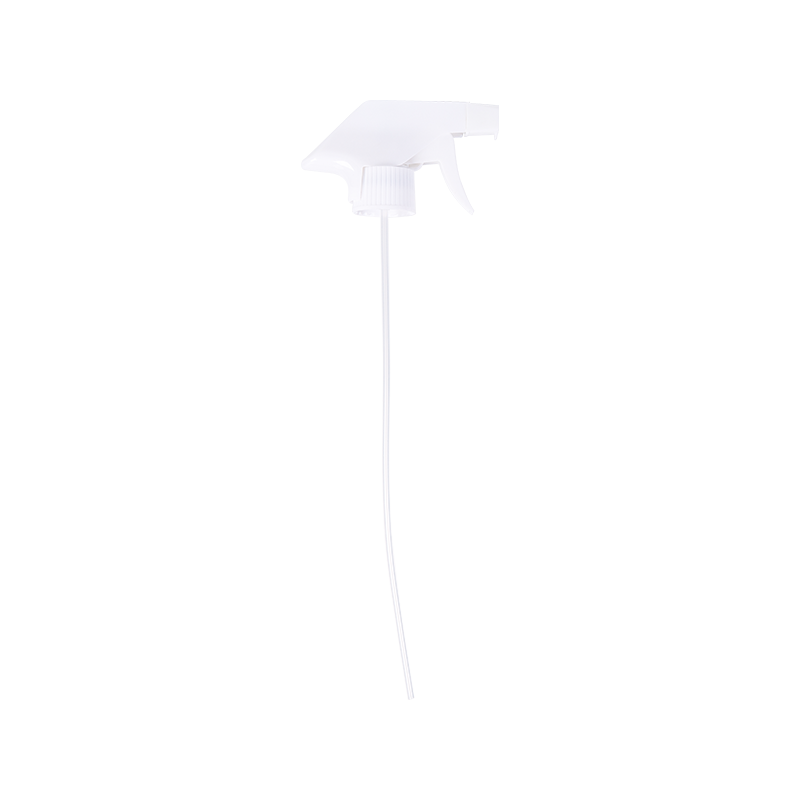

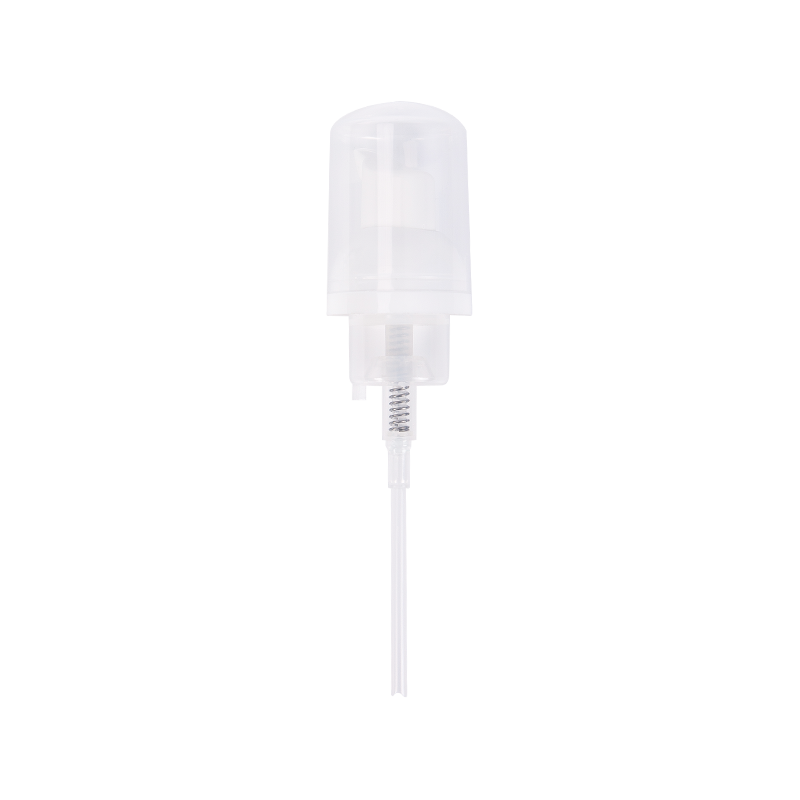

Remove the nozzle

Turn the nozzle counterclockwise, or press the buckle according to the design and pull it out (some models require tool assistance).

Record the direction or mark of the nozzle to keep the spray pattern consistent when reinstalling.

2. Cleaning steps

Nozzle cleaning

Clogging causes: liquid crystallization, particulate matter or dried residue.

Cleaning method:

Warm water soaking: Immerse the nozzle in 50-60℃ warm water for 10-15 minutes to soften the residue.

Physical dredging: Use a soft brush (such as a toothbrush) to gently scrub the inside of the nozzle.

Carefully pick out the blockage with a fine needle or toothpick (avoid damaging the nozzle hole).

Chemical dissolution:

Oily residue: Soak the nozzle with alcohol or special solvent.

Corrosive residue: Choose the corresponding solvent according to the material (for example, strong acid cleaners can be used for stainless steel nozzles, but avoid corrosive solvents from contacting non-stainless steel parts.

Pump body and pipe cleaning

Pump body internal cleaning:

Inject clean water or solvent, press the trigger repeatedly, and use pressure to discharge the residual liquid.

Pipe cleaning:

Insert a thin tube (such as a straw) into the pipette mouth, inject the solvent and shake the container.

External cleaning

Container surface: Wipe with a damp cloth to prevent water from penetrating into the threads or sealing rings.

Trigger and grip: Wipe with a soft cloth dipped in neutral detergent to avoid residue accumulation.

3. Drying and storage

Natural air drying: Turn the nozzle and container upside down and place them in a ventilated place to dry (avoid direct sunlight).

Compressed air assistance: Use an air gun (pressure ≤0.5 MPa) to dry the inside of the nozzle.

Storage recommendations:

When not in use for a long time, store the nozzle separately from the container to avoid aging of the sealing ring.

Store in a cool and dry place, avoid high temperature or freezing environment.

4. Precautions

Avoid violent disassembly: The nozzle cannot be forcibly poked with sharp objects, and must be dissolved or scrubbed in a gentle way.

Regular inspection: It is recommended to perform deep cleaning after every 50-100 uses.

Safety first: Wear protective equipment when handling corrosive liquids to avoid contact with skin or eyes.

5. Common Problems and Solutions

|

Problem |

Possible Cause |

Solution |

|

Nozzle Blockage |

Liquid crystallization, accumulation of particles |

Clean the nozzle as per the cleaning method mentioned above |

|

Trigger Jamming |

Spring aging or insufficient lubrication |

Apply lubricant or replace the spring |

|

Container Leakage |

Damaged or improperly installed sealing ring |

Replace the sealing ring and check the threaded connection |

中文简体

中文简体