Innovation in beauty packaging – the 84.9mm Black Lip Balm Lip Gloss Lipstick Capsule. Crafted with precision and elegance, this capsule is designed to elevate your lip care and cosmetic products to n...

What is the difference between a lotion pump and a treatment pump?

While both lotion and treatment pumps serve the purpose of dispensing liquid products from bottles, they are engineered with distinct mechanisms and for different viscosities and product types. Understanding these differences is crucial for brands in the cosmetics, skincare, and pharmaceutical industries to ensure optimal product delivery, preserve formulation integrity, and enhance consumer experience.

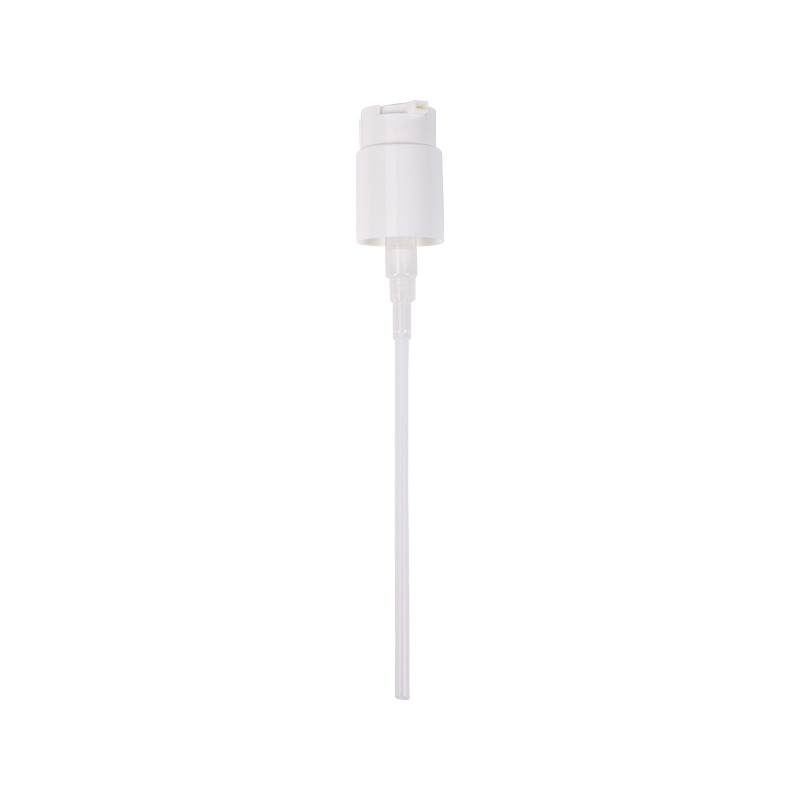

Lotion Pumps: Designed for Viscous Formulations

Lotion pumps, often referred to as cream pumps or dispenser pumps, are designed to handle thicker, more viscous formulations. Their construction is robust, allowing them to effortlessly dispense products like:

-

Body lotions and creams: The most common application, due to their rich and often opaque textures.

-

Shampoos and conditioners: Many hair care products have a significant viscosity.

-

Liquid soaps and hand sanitizers: These products are often formulated to be thicker to prevent excessive dispensing.

-

Sunscreens: Especially those with a creamy or balm-like consistency.

Key Features and Mechanics of Lotion Pumps:

-

Larger Dip Tube Diameter: To accommodate thicker liquids, lotion pumps typically have a wider dip tube, reducing the risk of clogging.

-

Stronger Spring Mechanism: The spring within a lotion pump is designed to handle the greater resistance of viscous fluids, providing a consistent and ample dose with each pump.

-

Higher Output Volume: Lotion pumps generally dispense a larger amount of product per actuation (e.g., 2cc, 4cc, or more). This makes them suitable for products where a generous application is desired.

-

Valve System: They often employ a ball-and-spring or similar valve system that can effectively draw up and push out thick formulations without leakage or air ingress.

-

Variety in Actuator Design: Actuators (the part you press) for lotion pumps can vary widely in shape and size, often designed for comfortable and repeated use with larger hands or for dispensing a substantial amount.

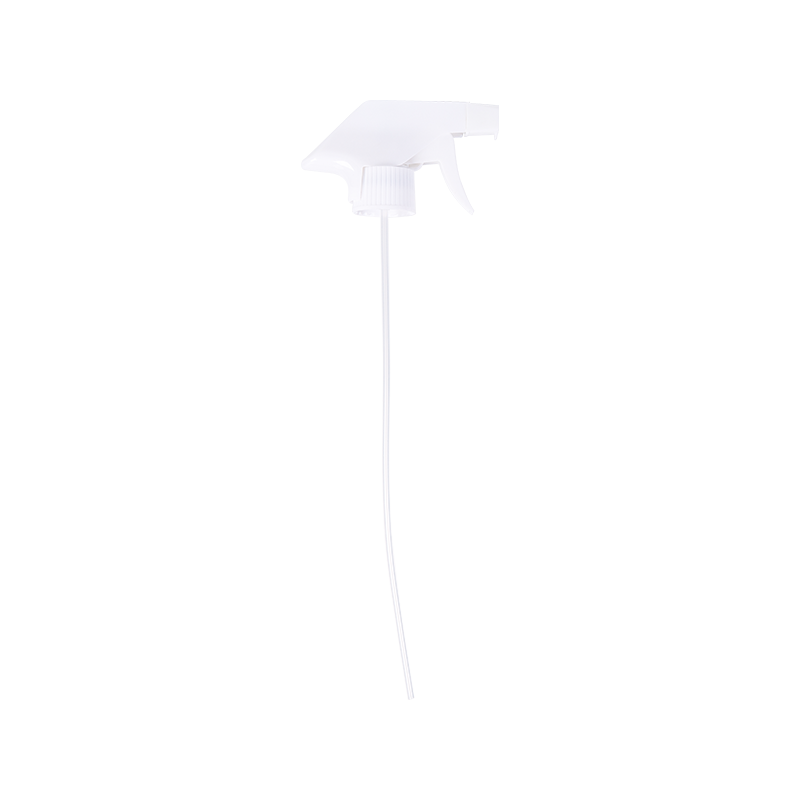

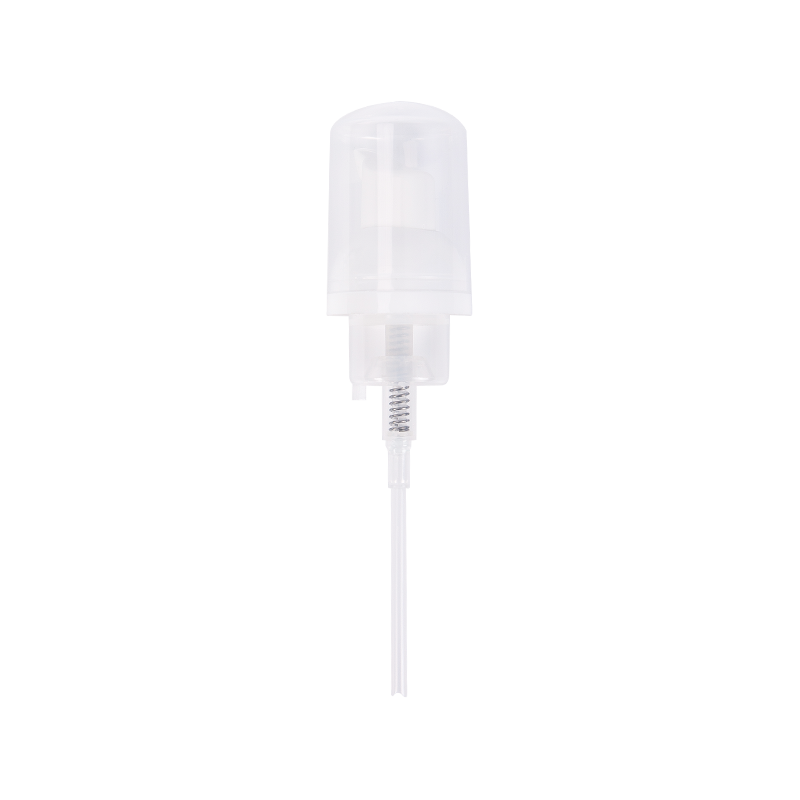

Treatment Pumps: Precision for Low-Viscosity and Sensitive Formulations

Treatment pumps, also known as serum pumps or fine mist pumps (though true fine mist pumps are a sub-category), are engineered for precise dosing of lower-viscosity and often more delicate formulations. These pumps are ideal for:

-

Serums: Often potent and expensive, requiring controlled application.

-

Essences and toners: Lighter liquids that need fine dispersion.

-

Lightweight lotions and gels: Products with a runnier consistency than traditional creams.

-

Liquid foundations: Where controlled, even dispensing is key for makeup application.

-

Pharmaceutical and active skincare products: Where precise dosage can be critical for efficacy and safety.

Key Features and Mechanics of Treatment Pumps:

-

Smaller Dip Tube Diameter: Designed for thinner liquids, the dip tube is narrower to facilitate smooth flow without drawing up excess air.

-

Finer Atomization or Smaller Droplet Size: While not always a "mist," treatment pumps are designed to dispense product in smaller, more controlled droplets or a finer stream compared to lotion pumps. This can be particularly important for serums that need to be absorbed quickly.

-

Lower Output Volume: Treatment pumps dispense a significantly smaller amount of product per actuation (e.g., 0.1cc, 0.2cc, 0.5cc). This precision is vital for potent formulations where even a small excess could lead to waste or over-application.

-

Airless Technology (Optional but Common): Many high-end treatment pumps incorporate airless technology. This design prevents air from entering the container, protecting sensitive formulations from oxidation and contamination, and ensuring almost 100% product evacuation.

-

Specialized Internal Components: Treatment pumps often feature more refined internal components and tighter tolerances to ensure accurate and consistent dosing with each pump.

-

Sleeker, More Elegant Design: Given their association with premium skincare and cosmetic products, treatment pumps often have a more minimalist and sophisticated aesthetic.

Choosing the Right Pump: A Critical Decision

The selection between a lotion pump and a treatment pump is not merely an aesthetic choice; it directly impacts product integrity, user experience, and ultimately, brand perception.

-

Product Viscosity: This is the primary determinant. A lotion pump will struggle with a very thin serum, potentially leading to leakage or an uncontrolled gush of product. Conversely, a treatment pump will fail to draw up or dispense a thick cream.

-

Desired Dosage: Consider how much product the consumer needs per application. A large dose for a body lotion versus a precise drop for a concentrated serum.

-

Formulation Sensitivity: For active ingredients prone to degradation from air exposure, an airless treatment pump is often the superior choice.

-

Target Market and Brand Positioning: Premium, high-value products often benefit from the precision and sophistication offered by treatment pumps. Everyday, high-volume products are typically suited for lotion pumps.

-

Cost Implications: Generally, treatment pumps, especially those with airless features, tend to be more expensive than standard lotion pumps due to their intricate design and manufacturing precision.

In conclusion, while both are dispensing mechanisms, lotion pumps are the workhorses for high-viscosity, high-volume applications, offering robust and generous dispensing. In contrast, treatment pumps are the precision instruments for low-viscosity, sensitive, and high-value formulations, ensuring controlled, accurate, and often air-protected delivery. Brands must partner with experienced packaging manufacturers to rigorously test and select the pump that perfectly complements their product's unique characteristics and meets consumer expectations.

中文简体

中文简体