Innovation in beauty packaging – the 84.9mm Black Lip Balm Lip Gloss Lipstick Capsule. Crafted with precision and elegance, this capsule is designed to elevate your lip care and cosmetic products to n...

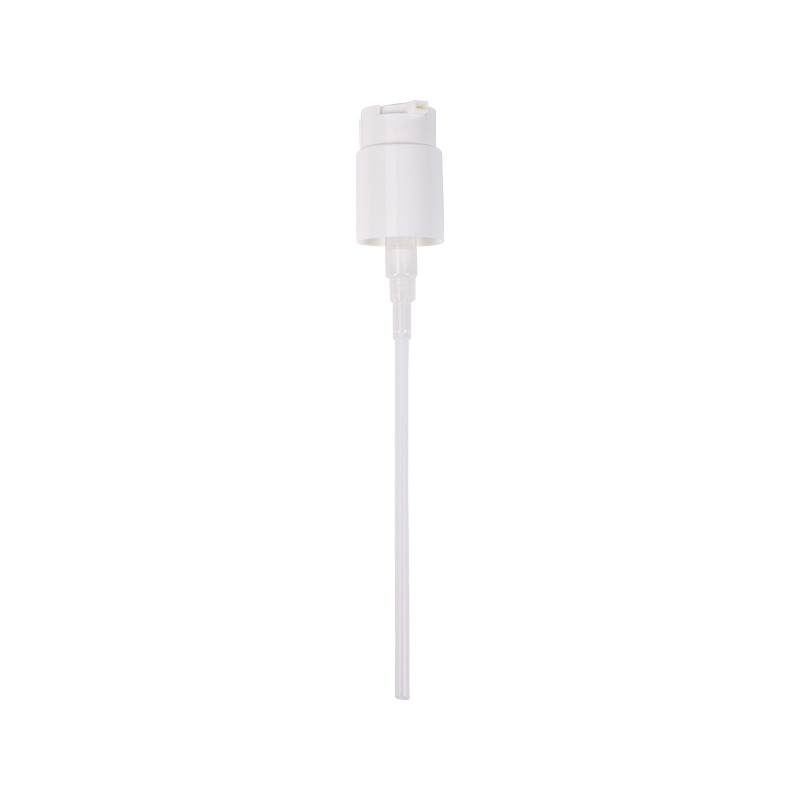

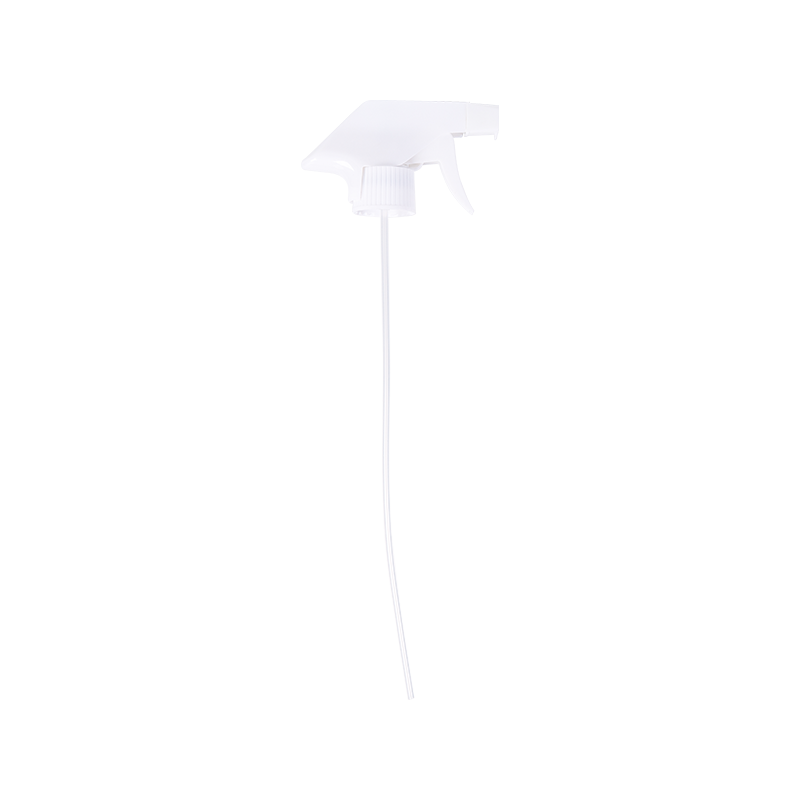

The Marvel of the Foam Pump

The Foam Pump, a seemingly simple dispensing device, is a marvel of mechanical engineering and chemical science. It's a key innovation that has transformed numerous industries, from cosmetics and personal care to pharmaceuticals and household cleaning. Unlike traditional pumps that dispense a liquid, the foam pump creates a luxurious, ready-to-use foam from a liquid formula, offering a unique user experience and tangible benefits.

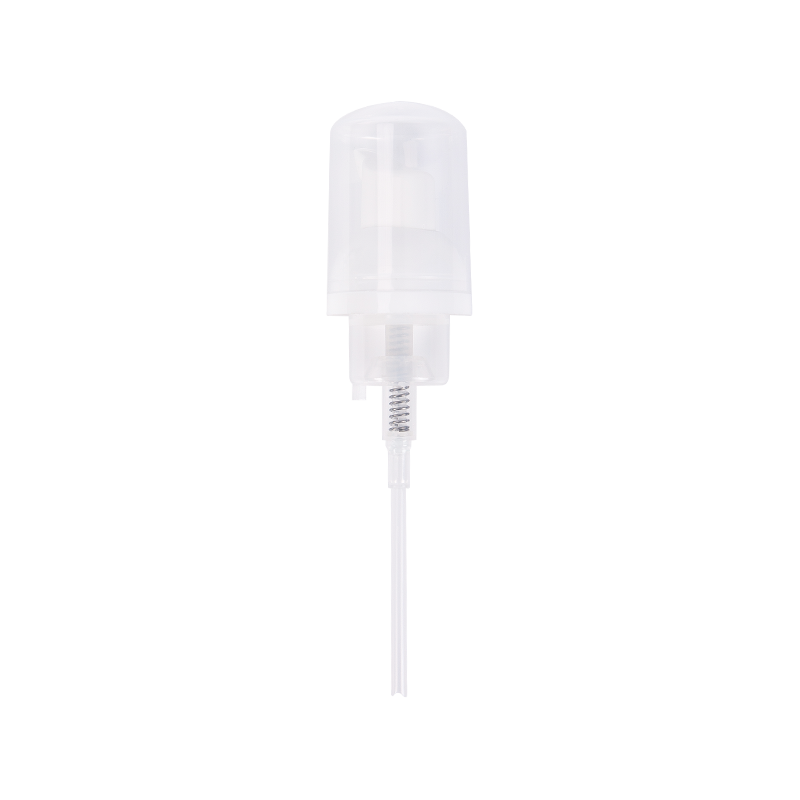

How the Foam Pump Works

The genius of the Foam Pump lies in its clever design. While there are several variations, the fundamental principle is the same: it introduces air into a liquid and mixes them to create a foam.

A typical foam pump consists of several main components:

-

Piston and Chamber: When the user presses the actuator, a piston moves down, creating pressure within a chamber.

-

Air and Liquid Inlets: As the piston moves, it draws a specific amount of liquid from the bottle and a precise amount of air from a small inlet.

-

Mixing Mesh: This is the most crucial part. The liquid and air are forced through one or more layers of a fine mesh screen (often made of plastic). This mesh breaks the mixture into tiny bubbles, transforming the liquid into a stable, rich foam.

-

Spring and Actuator: A spring returns the piston to its original position, ready for the next use.

This process ensures that each pump stroke delivers a consistent, high-quality foam, which is not only aesthetically pleasing but also highly effective.

The Benefits of Using a Foam Pump

The advantages of a Foam Pump extend beyond simple aesthetics. They offer significant benefits for both consumers and manufacturers.

For the Consumer:

-

Enhanced Efficacy: The foamed product provides a larger surface area, allowing it to spread more easily and evenly on the skin. This can improve the performance of cleansing agents, moisturizers, and other topicals.

-

Less Product Waste: Because the pump controls the dose and the foam expands the product volume, consumers tend to use less product per application, making the bottle last longer.

-

A Superior User Experience: The rich, soft texture of foam feels luxurious and pleasant to the touch, elevating a mundane task like handwashing into a more enjoyable ritual.

For the Manufacturer:

-

Reduced Ingredient Costs: Formulators can use less concentrated ingredients to achieve the same effect, as the foaming process makes the product more efficient. This can lead to significant cost savings.

-

Eco-Friendly: By using a foam pump, manufacturers can often reduce the amount of propellant gases, which are commonly found in aerosol foams, making their products more environmentally friendly.

-

Versatility in Formulations: The Foam Pump is not just for soaps. It's ideal for a wide range of products, including hair mousses, shaving creams, facial cleansers, and even pet shampoos.

The Future of the Foam Pump

The Foam Pump is continually evolving. Innovations are focused on creating pumps with even higher foam quality, greater consistency, and more sustainable materials. As the demand for convenient, efficient, and eco-conscious products grows, the foam pump will undoubtedly remain a key player in the packaging and personal care industries.

中文简体

中文简体