Innovation in beauty packaging – the 84.9mm Black Lip Balm Lip Gloss Lipstick Capsule. Crafted with precision and elegance, this capsule is designed to elevate your lip care and cosmetic products to n...

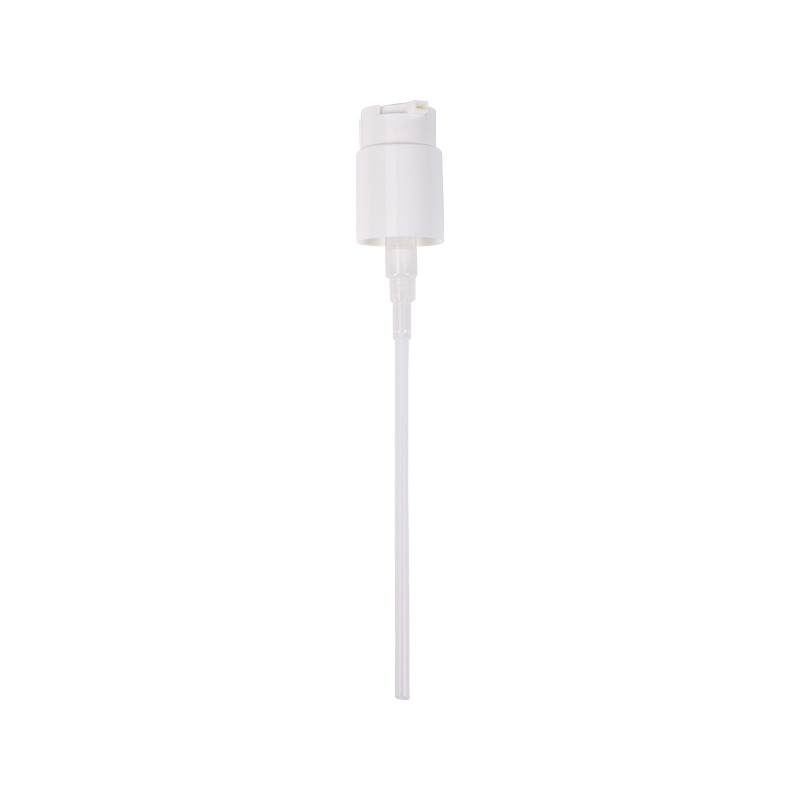

The Lotion Pump: A Silent Innovator in Modern Life

Have you ever stopped to think about how that small pump head you press every morning precisely delivers lotion, shampoo, or hand soap into your hand? This seemingly insignificant device is the subject of our discussion today: the lotion pump. It's more than just a simple container accessory; it's a core component of modern packaging design and daily convenience.

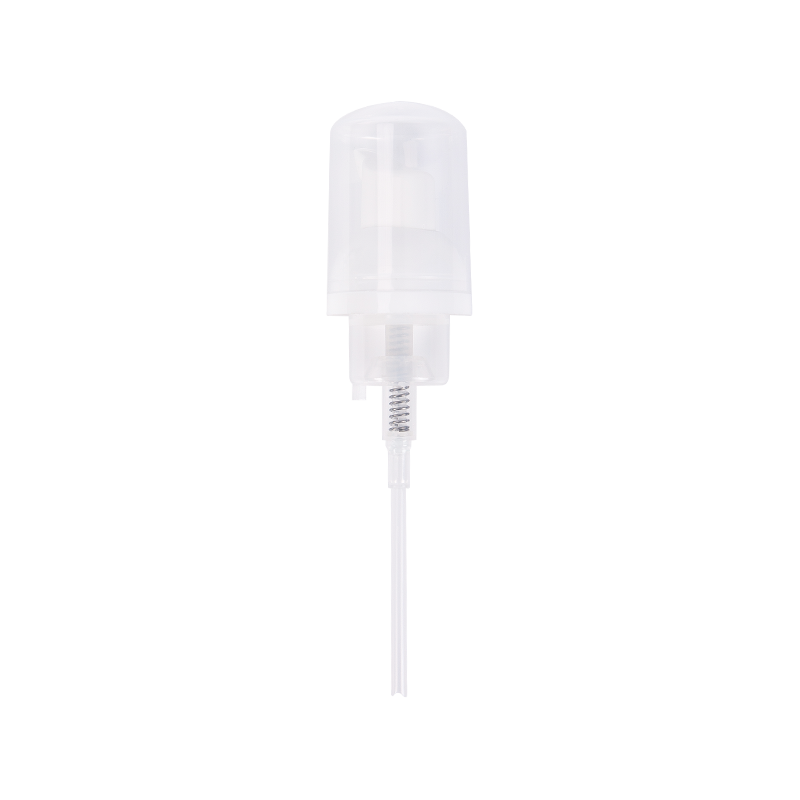

The Working Principle of a Lotion Pump: Simplifying Complexity

The working principle of a lotion pump is a clever application of physics. It primarily consists of an actuator, a pump body, a piston, and a dip tube. When you press the actuator, the piston moves down, expelling air. Simultaneously, the lotion below the piston is drawn into the pump chamber. When you release the actuator, the spring inside the pump body pushes the piston back to its original position. During this process, the lotion is forced up the dip tube and out through the small opening in the actuator.

This ingenious design ensures that each press provides a stable, measured amount of liquid, preventing the waste and contamination that can occur with traditional pour-style bottles.

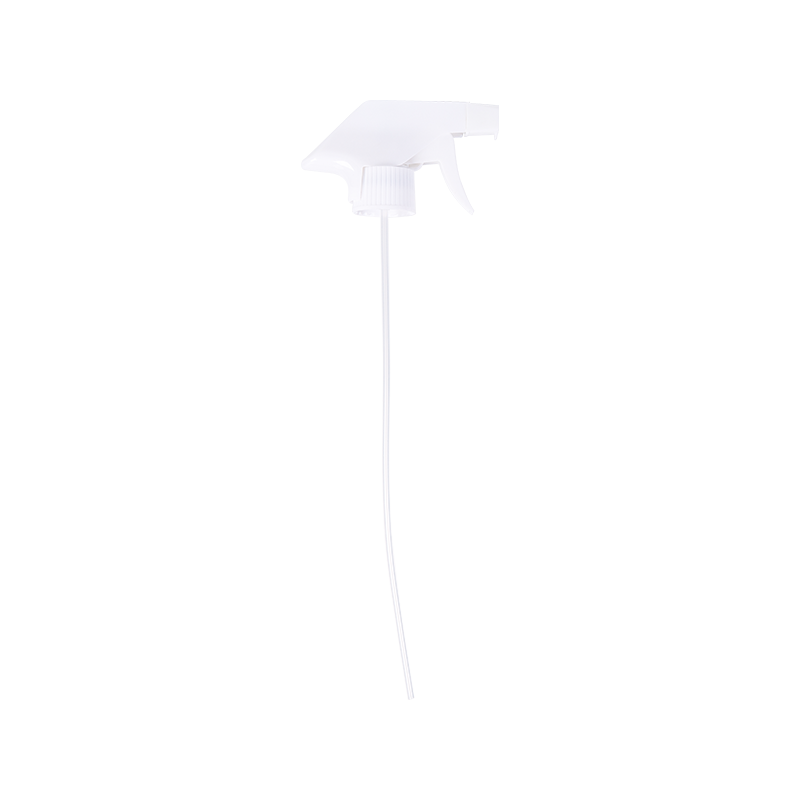

Professional Classifications and Materials of Lotion Pumps

To meet the needs of different products, the lotion pump comes in a wide variety of types and materials. Based on their use, they can be classified as:

-

Standard lotion pump: Used for lotions, creams, and other products with a medium viscosity.

-

Foam pump: Through a special design, it mixes liquid and air to produce rich, fine foam.

-

Spray pump: Atomizes liquid into tiny particles, used for products like perfumes and toners.

-

Airless pump: A high-end lotion dispenser that uses a piston to push the contents upward, completely isolating the product from air. This is highly effective for protecting skincare products that are sensitive to oxidation.

In terms of materials, lotion pumps are typically made from plastics like polypropylene (PP) and polyethylene (PE). These materials are not only chemically resistant, allowing them to safely come into contact with various cosmetics and cleaning agents, but they are also cost-effective and easy to mass-produce.

Industry Outlook: Sustainability and Innovation

As consumers become more environmentally conscious, the development of the lotion pump is also moving toward sustainability. Recyclable materials, refillable designs, and lighter-weight structures are becoming new trends in the industry. Additionally, smart lotion pumps are emerging; they can monitor usage and even connect to smart home systems to provide a more personalized user experience.

From its origins as a simple liquid delivery device to its current role as a hygienic, eco-friendly, and intelligent component, the lotion pump is changing our lives in its own unique way. The next time you use one, take a moment to appreciate the convenience and ingenuity brought by this silent innovator.

中文简体

中文简体