Innovation in beauty packaging – the 84.9mm Black Lip Balm Lip Gloss Lipstick Capsule. Crafted with precision and elegance, this capsule is designed to elevate your lip care and cosmetic products to n...

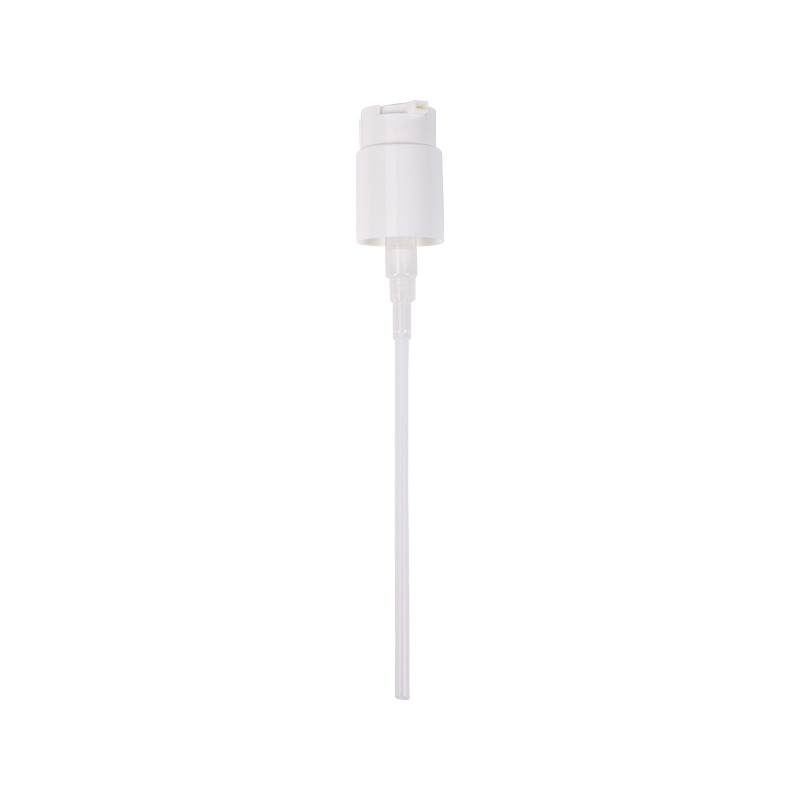

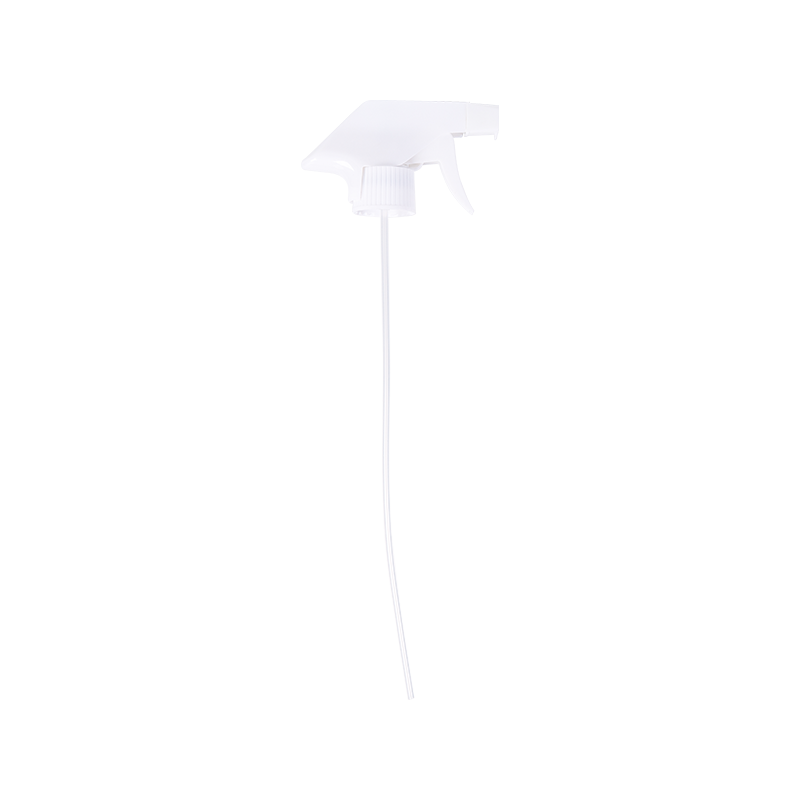

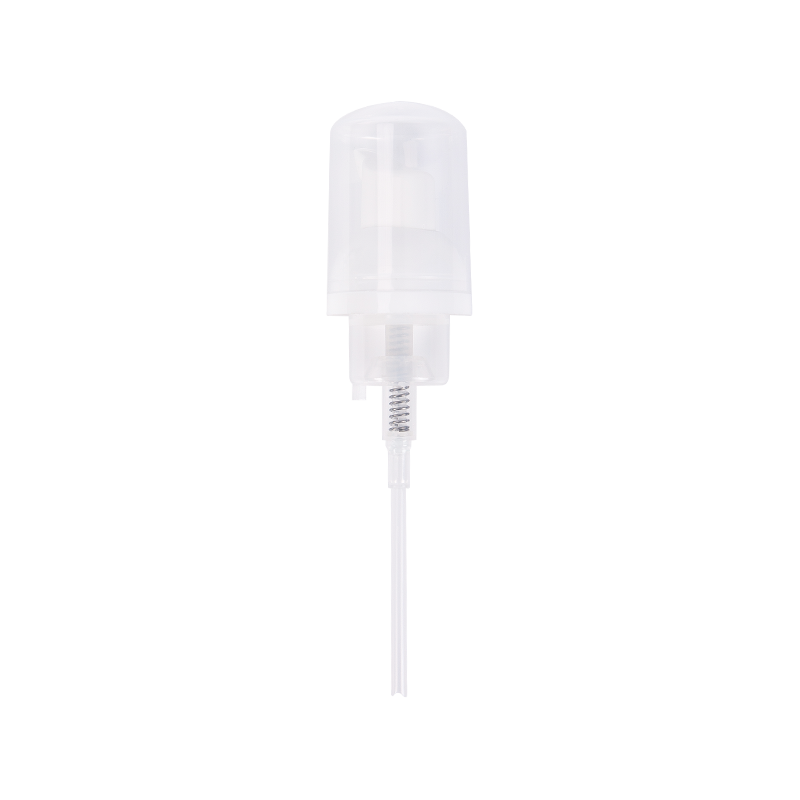

How does a foam pump work?

A foam pump is a non-aerosol dispensing device designed to deliver liquid products in the form of foam. These pumps are widely used in cosmetic, personal care, household, and industrial applications to provide an efficient and pleasant user experience. The mechanism of a foam pump is significantly different from traditional liquid or spray pumps, relying on a unique air-liquid mixing process and foam-generating mesh system.

1. Core Components of a Foam Pump

A typical foam pump consists of the following essential components:

-

Actuator (Pump Head): The top part pressed by the user. It initiates the dispensing process.

-

Pump Engine (Spring Mechanism): Provides the force needed to draw and push fluids and air.

-

Foaming Chamber: The mixing area where liquid and air blend to form foam.

-

Mesh Screen or Foam Net: A fine grid that helps convert the liquid-air mixture into foam bubbles.

-

Air and Liquid Inlets: Two channels for drawing air from the environment and liquid from the bottle.

-

Dip Tube: A tube reaching into the liquid product at the bottom of the container.

2. The Foam Generation Process: Step-by-Step

Step 1: Actuation

When the user presses down on the actuator, it compresses the internal spring and reduces pressure inside the pump housing. This creates suction.

Step 2: Suction of Air and Liquid

Two separate inlets allow:

-

Air to be drawn from outside the pump into the mixing chamber.

-

Liquid product to be drawn upward through the dip tube.

Step 3: Air-Liquid Mixing

The air and liquid are simultaneously forced into the foaming chamber, usually in a ratio of approximately 1:3 or 1:4 (liquid to air). This carefully calibrated ratio is essential to produce stable and uniform foam.

Step 4: Dispersion Through Mesh

The air-liquid mixture is then pushed through one or more layers of fine mesh screens or netting. This physical shearing action divides the fluid into micro-bubbles, forming a dense and creamy foam.

Step 5: Foam Dispensing

The generated foam is then expelled through the nozzle and into the user's hand. The foam is pre-aerated, requiring no further lathering.

3. Design Considerations

-

Viscosity of Liquid: Foam pumps require low-viscosity (thin) liquids. High-viscosity or gel-like liquids may not foam effectively.

-

Foaming Agent: The liquid must contain surfactants or foaming agents to create bubbles.

-

Valve Type: Check valves prevent backflow and help maintain consistent pressure.

-

Spring Strength and Material: Determines the responsiveness and longevity of the pump.

-

Mesh Size: Smaller mesh holes produce finer foam but may clog more easily.

4. Applications of Foam Pumps

-

Personal Care Products: Foaming hand soap, facial cleansers, shaving creams.

-

Cosmetics: Mousse foundations, makeup removers.

-

Household Cleaners: Surface foam cleaners, dishwashing solutions.

-

Medical and Industrial Use: Antiseptic foams, disinfectants.

5. Advantages of Foam Pump Systems

-

Eco-Friendly: Allows for lower chemical usage due to dilution.

-

Cost-Effective: Reduces product consumption while maintaining performance.

-

Enhanced User Experience: Delivers soft, ready-to-use foam instantly.

-

No Aerosols Required: Safer and more sustainable alternative to pressurized cans.

6. Limitations

-

Not suitable for viscous liquids unless specially formulated.

-

Foam quality may degrade with improper formulation or faulty mesh.

-

Exposure to high temperatures or harsh chemicals may reduce pump lifespan.

Conclusion

Foam pumps operate on a precise balance of fluid dynamics, air induction, and mechanical dispersion. Their effectiveness lies in the synergy between air-liquid ratio, structural design, and the nature of the foaming product. As consumer preferences shift toward sustainability and convenience, foam pumps continue to gain popularity across various industries due to their efficiency, cost-saving potential, and user appeal.

中文简体

中文简体