Innovation in beauty packaging – the 84.9mm Black Lip Balm Lip Gloss Lipstick Capsule. Crafted with precision and elegance, this capsule is designed to elevate your lip care and cosmetic products to n...

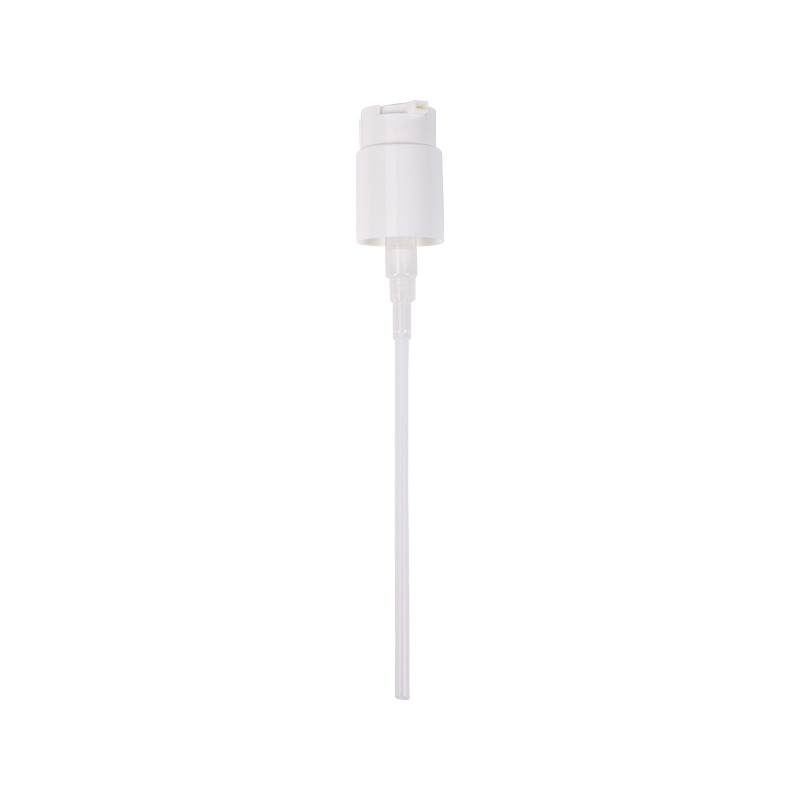

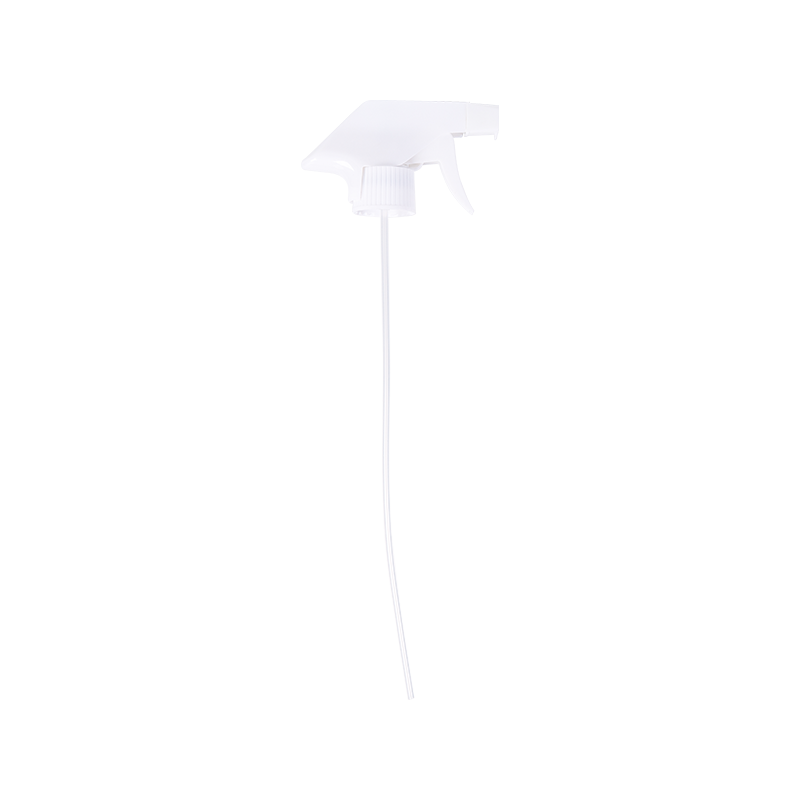

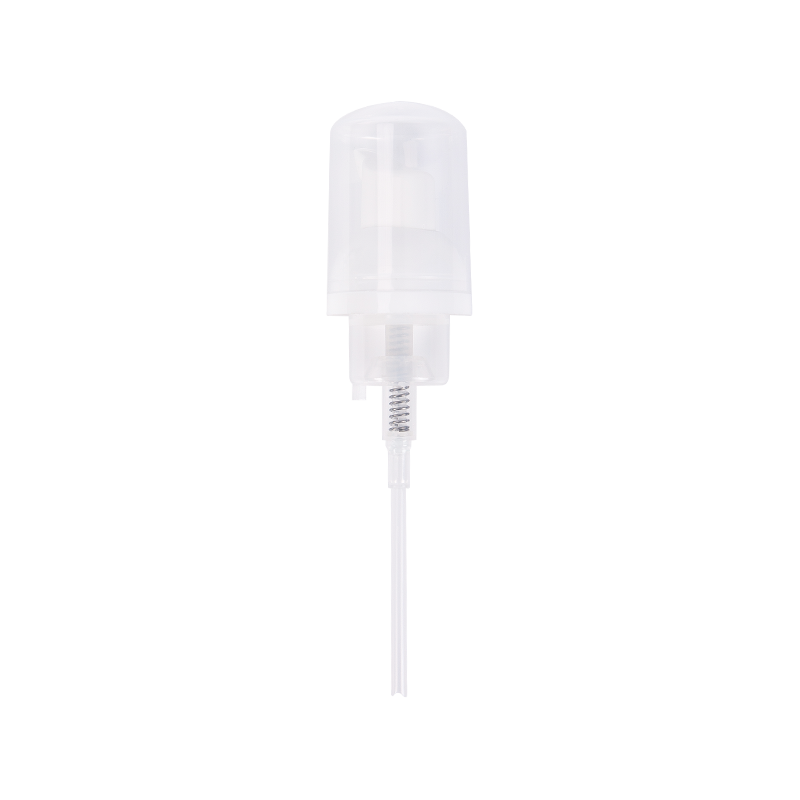

Foam pump vs. regular pump

Choosing the right dispenser for your product is more than just a packaging decision; it's a key part of the user experience. The two most common types are the foamer pump and the regular pump, and while they might look similar, their internal mechanisms and ideal applications are quite different.

How They Work: The Core Difference

A regular pump operates on a simple piston-action mechanism. When you press the pump head, a piston creates a vacuum that draws the liquid product from the bottle into a chamber. The product is then pushed out through the nozzle in its original liquid form. This simple design is effective for a wide range of products, from thick lotions to thin shampoos.

In contrast, a Foam Pump (also known as a foaming soap dispenser or foaming pump mechanism) is an elegant piece of engineering designed specifically to create foam. Inside the pump, a chamber mixes a diluted liquid solution with air. When you press the pump head, this air-liquid mixture is forced through a fine mesh screen. The mesh acts as a sieve, breaking the liquid into tiny bubbles and dispensing a rich, ready-to-use foam. This aeration process is what sets it apart.

When to Choose a Foamer Pump

Foamer pumps are a perfect choice when the product's effectiveness and user experience are enhanced by a foamy texture.

-

Product Efficiency: Because the foam is pre-lathered, it spreads easily and effectively on the skin or surfaces, meaning users need less product per use. This can make a bottle last longer, reducing waste and saving money for both consumers and businesses.

-

Enhanced User Experience: The luxurious feel of dense, creamy foam is a major selling point for products like facial cleansers, hand sanitizers, and body washes. It provides a more tactile and enjoyable experience that encourages repeat use.

-

Ideal for Specific Formulas: Foaming pump mechanisms require a specific low-viscosity formula. These formulations don't need the lathering agents found in many traditional soaps, making them a more eco-friendly and gentle option.

-

Less Water Usage: The pre-lathered foam requires less water to rinse off, which is a subtle but significant benefit for water conservation.

When to Choose a Regular Pump

Regular pumps are the workhorse of the packaging world, offering reliability and versatility for a wide array of products.

-

Viscous Products: Regular pumps can handle thick, viscous liquids that a foaming pump cannot, such as lotions, creams, conditioners, and gels. Trying to put a thick liquid in a foaming dispenser would likely clog it and prevent it from working properly.

-

Direct Application: For products that need to be applied directly as a liquid, such as liquid hand soap, shampoo, or many hair care products, the regular pump is the only choice. It delivers the product in a concentrated form, ready for the user to lather.

-

Simplicity and Cost: Due to their straightforward design, regular pumps are often more cost-effective to produce, making them a common choice for a wide range of consumer goods.

The Bottom Line

The choice between a foaming dispenser and a regular pump comes down to the specific product, its viscosity, and the desired user experience. If your goal is to deliver a delightful, efficient, and gentle foam, the foamer pump is the clear winner. If your product is thick, requires direct liquid application, or needs a more straightforward and cost-effective dispensing method, the regular pump remains the industry standard.

中文简体

中文简体