Innovation in beauty packaging – the 84.9mm Black Lip Balm Lip Gloss Lipstick Capsule. Crafted with precision and elegance, this capsule is designed to elevate your lip care and cosmetic products to n...

Airless Advantage: Preserving Product Integrity

In the realm of high-efficacy skincare and cosmetic formulations, packaging is far more than a mere container; it is a critical component in maintaining product integrity, stability, and shelf-life. For oxygen-sensitive products—such as those rich in delicate antioxidants, unstable vitamins (like Vitamin C), or prone-to-rancidity natural oils—the choice of packaging becomes paramount. In this context, the Airless Bottle system offers specific, significant advantages over traditional pump or jar packaging.

The Vulnerability of Traditional Packaging

Traditional packaging methods, while ubiquitous, present inherent weaknesses when dealing with oxygen-sensitive ingredients:

Jars and Pots

Jar packaging requires the user to dip their fingers or a spatula into the product. This action repeatedly exposes the entire contents to ambient air (oxygen) and contaminants (bacteria, dirt). Each opening and use promotes oxidation and microbial growth, rapidly degrading active ingredients and reducing the product’s effective shelf-life. This is particularly detrimental to natural oils, which quickly go rancid when exposed to oxygen.

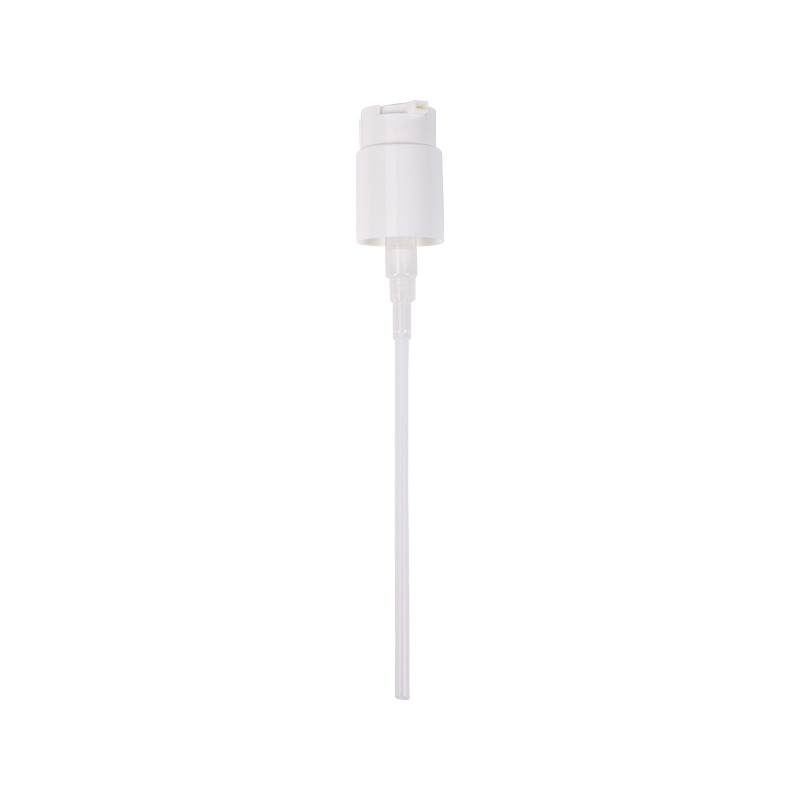

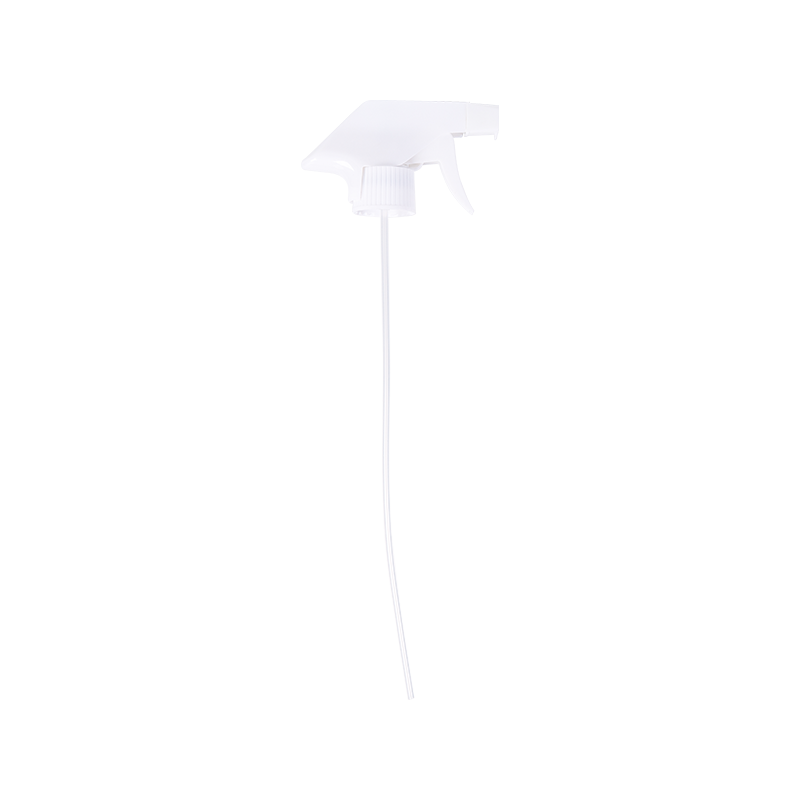

Conventional Pumps and Droppers

Standard pump bottles utilize a dip tube. As the product is dispensed, the vacuum created within the container is typically compensated by drawing in ambient air through a small vent or around the pump mechanism. Dropper bottles are similarly problematic, as drawing product out requires replacing that volume with air. This repeated cycle of air intake introduces oxygen directly into the headspace, where it can continually react with the sensitive formulation, compromising stability and efficacy over time.

The Specific Advantages of the Airless Bottle

The Airless Bottle system is engineered to isolate the product entirely from the external environment, offering superior preservation mechanics.

1. Superior Oxygen Barrier and Isolation

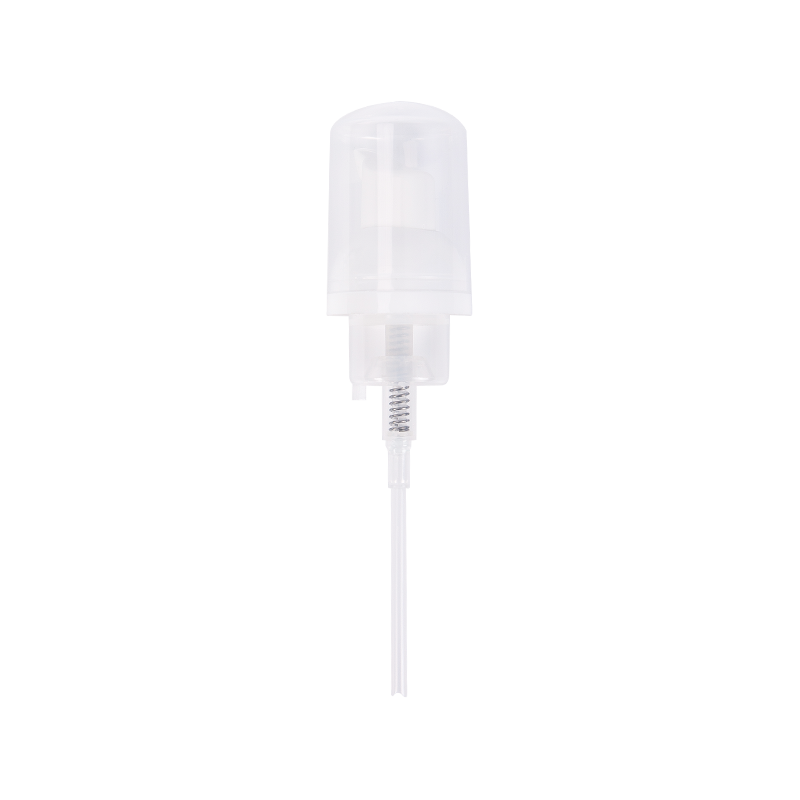

The core benefit of the Airless Bottle is its non-venting design. Instead of relying on a dip tube and venting air intake, airless packaging utilizes a piston mechanism or a collapsible pouch. When the pump is pressed, the mechanism dispenses the product, and a piston at the bottom of the container rises (or the pouch collapses) to fill the empty space.

- Continuous Seal: This mechanism ensures that no outside air ever enters the container to replace the dispensed volume, thus preventing direct contact between the product and atmospheric oxygen.

- Headspace Elimination: The piston rises and follows the product level, effectively eliminating the headspace where air traditionally pools, a critical point of oxidation in conventional systems.

2. Enhanced Chemical Stability and Efficacy

By eliminating oxygen exposure, airless bottles significantly retard the rate of oxidation and hydrolysis for vulnerable ingredients:

- Vitamin Preservation: Unstable vitamins, like L-Ascorbic Acid (Vitamin C) or retinol (Vitamin A), lose their potency rapidly when oxidized. Airless technology maintains their chemical structure, ensuring the consumer receives the full, advertised benefit of the active ingredient throughout the product’s life.

- Rancidity Prevention: Natural oils, such as rosehip or sea buckthorn oil, contain polyunsaturated fatty acids that are highly susceptible to rancidity (spoilage via oxidation). The airless barrier prolongs the freshness and therapeutic quality of these oils.

3. Extended Shelf-Life and Reduced Need for Preservatives

The inherently hygienic and sealed environment provided by the airless system offers a practical extension of the product’s shelf-life.

- Microbial Protection: Since fingers and external contaminants can never touch the bulk product, the risk of microbial contamination is drastically reduced.

- Minimal Preservative Load: The enhanced stability and protection against both oxidation and microbial ingress allow formulators to potentially use fewer or milder preservatives, a significant advantage for ‘clean beauty’ brands and consumers with sensitive skin.

4. Near-Total Product Evacuation

Beyond preservation, the airless mechanism offers superior functionality. The rising piston scrapes the sides of the container, allowing for a 95–100% evacuation rate. This reduces product waste, delivering better value to the consumer compared to conventional packaging where a significant amount of product can remain stuck to the bottom or sides, unreachable by a dip tube.

Conclusion: The New Standard for Sensitive Formulations

For any brand prioritizing the delivery of highly effective, stable, and clean formulations, the Airless Bottle is no longer a luxury but a fundamental necessity. Its unique ability to eliminate air ingestion, isolate the product, and facilitate hygienic, complete dispensing firmly establishes it as the gold standard for packaging oxygen-sensitive and preservative-light cosmetic and skincare products. This specialized packaging ensures that the product delivered to the consumer’s skin is as potent and stable as the day it was formulated.

中文简体

中文简体